When it comes to processing ingredients in industries like pharmaceuticals, food production, or cosmetics, a high-shear mixer plays a critical role. Its ability to create uniform blends, reduce particle size, and emulsify substances efficiently makes it a popular choice in many industries.

Here are six essential things you need to know about high-shear mixers:

What is a high-shear mixer? A high-shear mixer is a machine designed to mix materials with varying consistencies, creating a uniform and homogenous blend.

It works by using high mechanical forces to break down particles and disperse them evenly throughout the mixture. This is particularly useful in processes that require emulsification, like combining oil and water or breaking down large particles into smaller ones for better absorption.

Example: Think about making salad dressing at home. Without enough mixing force, oil and vinegar separate. A high-shear mixer would prevent that by breaking the oil particles down and dispersing them into the vinegar for a smooth, consistent dressing.

A high-shear mixer uses a rotor-stator mechanism, where the rotor spins rapidly within a stationary stator. As the ingredients pass through the tiny gaps between the rotor and stator, they are subjected to intense shear forces. These forces break the materials down into smaller particles, which allows for a more uniform mixture.

The rotor’s speed is crucial for the mixing process. The faster the rotor spins, the more shear force it generates, making the mixing process quicker and more efficient. The key element here is the tip speed, which determines the rate at which the ingredients are mixed.

High-shear mixers are versatile machines used in a variety of industries. Here are a few examples:

One of the primary benefits of using a high-shear mixer is the ability to create uniform, homogenous mixtures in a short amount of time. Here’s why high-shear mixers stand out:

Not all high-shear mixers are the same. Here are the main types:

Each type of high-shear mixer has its specific use case, depending on the scale and complexity of the process.

Like any piece of equipment, proper maintenance is key to ensuring the longevity and efficiency of a high-shear mixer. Regular cleaning and inspection of the rotor-stator assembly are crucial to avoid wear and tear, which can affect the mixer’s performance over time.

Additionally, when choosing a high-shear mixer, it’s important to consider:

Interested in learning more about how high-shear mixers can enhance your production process? Contact us today for expert guidance and recommendations tailored to your needs.

High-shear mixers are primarily used for liquids and wet materials. If you’re dealing with dry powders, a low-shear mixer or a specialized powder mixer may be more appropriate.

In wet granulation, high-shear mixers help form granules by combining powders with a liquid binder, resulting in a cohesive mixture that is easy to process into tablets.

Yes, high-shear mixers are designed to handle a wide range of viscosities, from thin liquids to thick pastes.

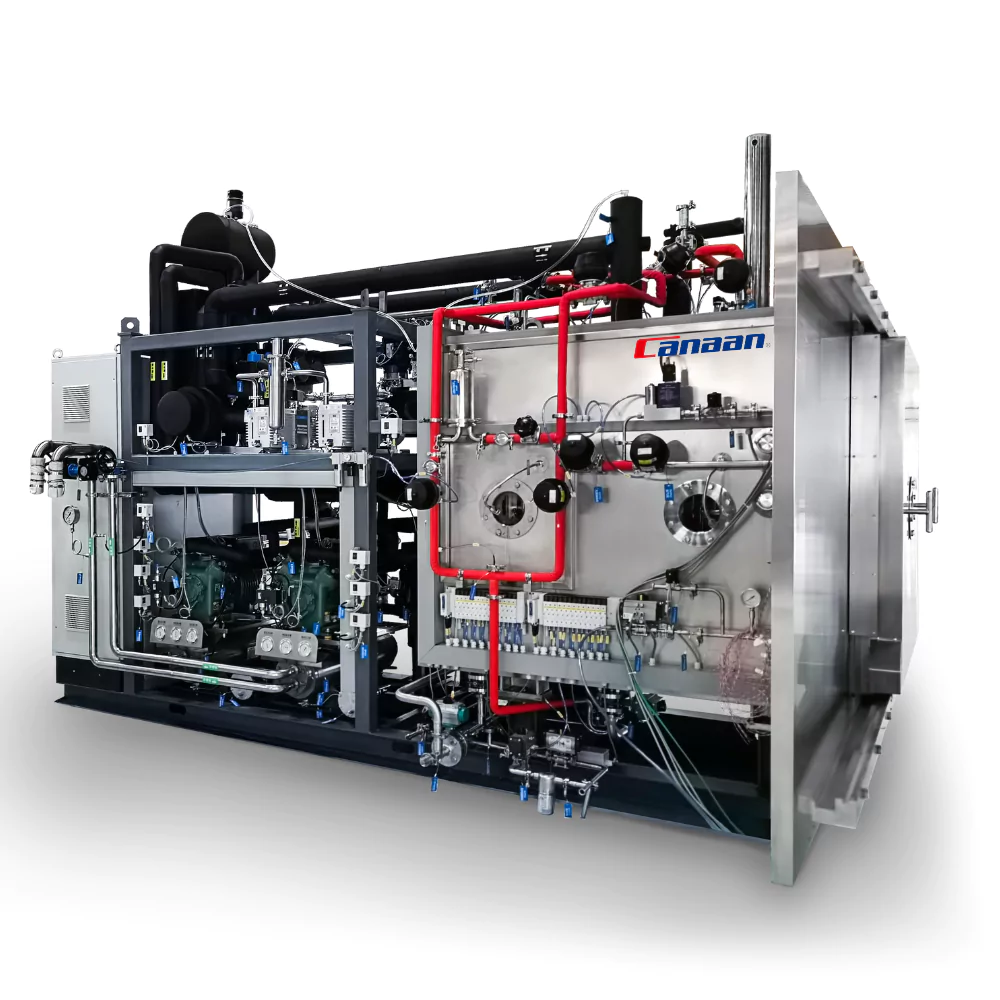

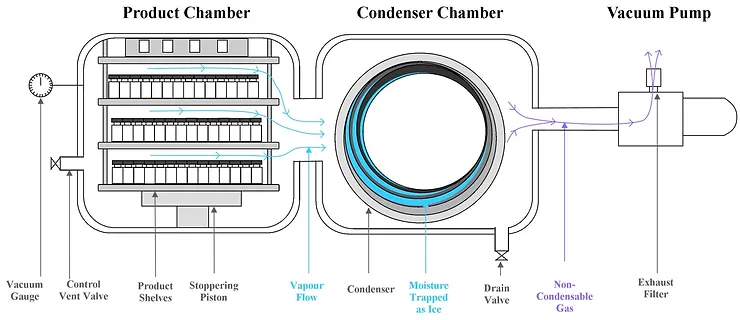

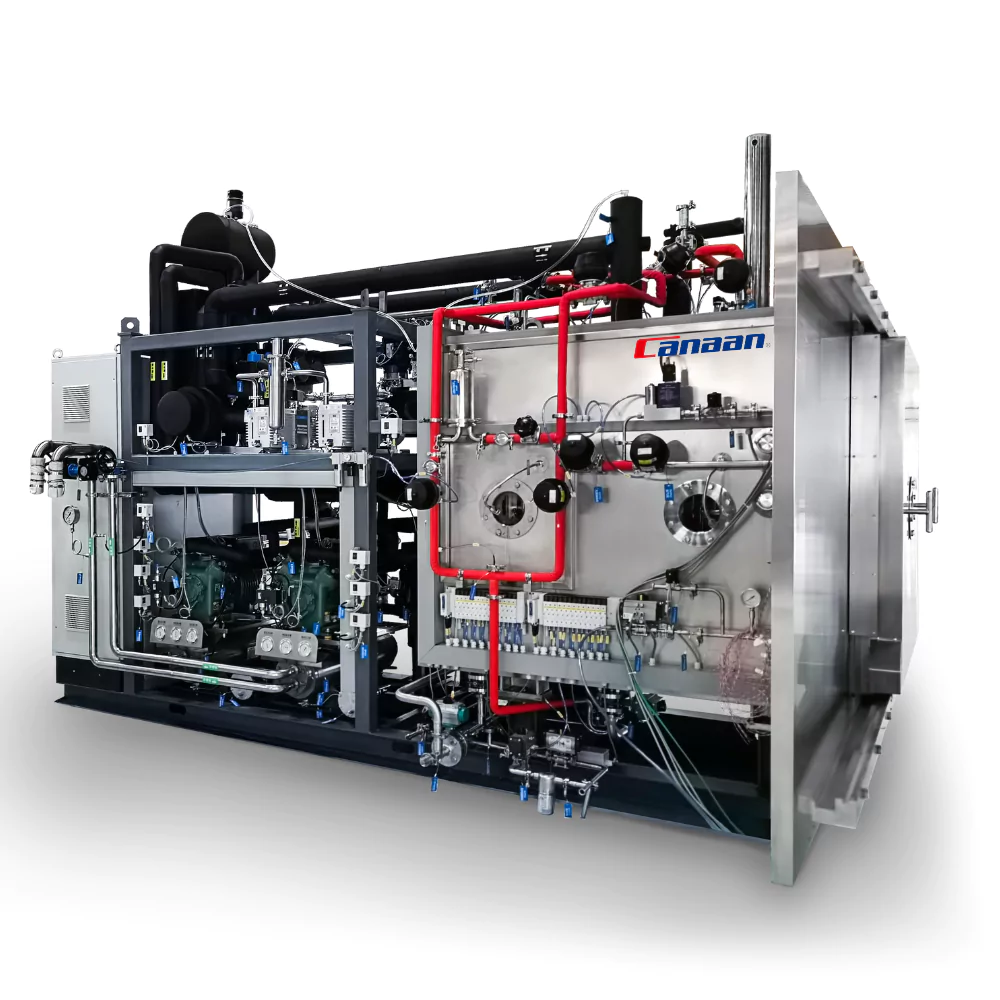

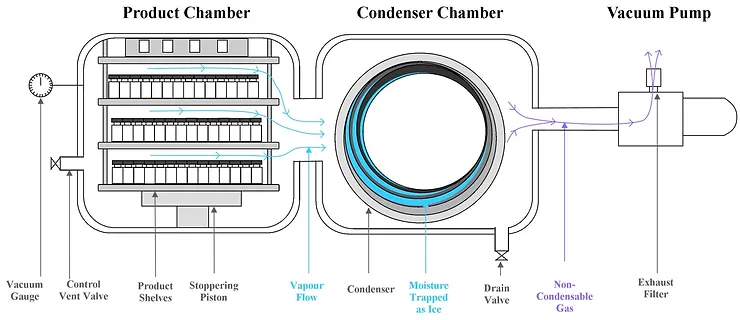

What is lyophilization? Freeze-drying, or lyophilization, is an important process in the pharmaceutical industry. It helps preserve medicines, vaccines, and other sensitive products by removing moisture. If you buy a used freeze-dried machine, it’s essential to take proper care of it. Proper maintenance will extend the machine’s life, improve efficiency, and ensure the safety and […]

What is freeze-drying? Freeze drying, also called lyophilization, is a method used to preserve medicines, vaccines, and other sensitive products. It removes moisture from products, which helps them stay stable for longer. In the pharmaceutical industry, freeze-drying is key to storing important products, like biologics and vaccines, without needing refrigeration. For freeze-drying to work, you […]

In the pharmaceutical industry, two common methods for drying products are freeze-drying and spray-drying. These methods remove water from products like medicines and vaccines, making them last longer and easier to store. But how do they work? And which one is better for different types of products? Let’s explore the differences between freeze-drying and spray-drying, […]