Every pill tells a story of science, precision, and the amazing machines that bring them to life. Tablet press machines are the secret heroes behind the medicines we trust. They turn powders into the tablets we swallow without a second thought.

But these machines aren’t one-size-fits-all. From small presses making a few pills at a time to giants churning millions, each has a job to do.

Let’s pull back the curtain and see how these metal marvels shape the world of medicine, one tablet at a time.

| Type of Tablet Press | Description | Key Features |

| Single Punch | Makes one tablet at a time. | Easy to use, affordable, compact. |

| Rotary | Produces many tablets continuously. | High-speed, hundreds to thousands per minute. |

| Multi-Layer | Creates tablets with multiple layers. | Ideal for combination drugs. |

| Special | Includes specific types of presses. | – Bilayer: Two-layer tablets. |

| – Mini: Very small tablets. | ||

| – Effervescent: Fizzy tablets. | ||

| High-Speed | Extremely fast production. | Up to a million tablets per hour. |

| R&D | For research and development of new medicines. | Flexible for testing different ideas. |

What is a single punch table press? A single-punch tablet press is a simple tablet machine that makes one tablet at a time using one set of punches and dies. It’s perfect for small jobs and testing new ideas.

This press is like a trusty old tool. It’s not fast, but it gets the job done well. Small drug stores, labs, and new companies often use these. They’re easy to use, cheap to buy, and don’t take up much space.

When you need to make lots of tablets fast, the rotary press is the way to go. Picture a big wheel with many stations. Each station has punches and dies. As the wheel turns, it keeps making tablets non-stop.

Rotary presses come in different sizes:

Think of it like a merry-go-round that makes tablets. Every turn makes a batch of pills. Bigger machines make more pills but need more room and money.

Big drug companies use these to make millions of tablets each day. They’re great for making the same kind of pill for a long time. They work fast and don’t need someone to feed them powder all the time.

Sometimes, one layer in a tablet isn’t enough. That’s where multi-layer presses come in. What’s a multi-layer tablet press? A multi-layer tablet press is a special machine that can make tablets with two or more layers. This opens up new ways to make pills work better.

People use these for:

Making a multi-layer tablet is like building a tiny sandwich. The machine puts down one layer of powder, presses it a little, then adds another layer. It does this until all layers are there, then presses it all together into one tablet.

Different pills need different machines. Here are some special types:

This makes two-layer tablets. It’s simpler than machines that make many layers, but more complex than ones that make single-layer pills.

This makes very small tablets, smaller than a grain of rice. These tiny pills are great for kids’ medicine or pills that need to go to a specific part of the body.

This makes the fizzy tablets that dissolve in water. It works in a special room where the air is very dry, so the tablets don’t start fizzing too soon.

When you need to make tablets really fast, high-speed presses are the answer. These machines are like the race cars of the tablet world. They can make up to a million tablets every hour. That’s more than 16,000 tablets a minute!

But they’re not just fast. They’re smart too. They check each tablet to make sure it’s the right weight and hardness. If something’s not right, they fix it right away. It’s like having a super-fast chef who tastes every dish and makes it perfect, all in the blink of an eye.

For scientists working on new medicines, there’s the R&D press. This machine is like a Swiss Army knife for making tablets. It can change how it works very quickly, letting researchers try out lots of different ideas.

An R&D press might only make a few hundred tablets an hour, but each one teaches the scientists something new. These machines can measure all sorts of things about each tablet. This helps in creating new drugs and making sure they’ll work well when made in big batches.

Picking the right tablet press is like choosing the right car. It depends on what you need. A small drug store might only need a simple single punch press. A big company making millions of pills a day needs a high-speed rotary press.

But it’s not just about size and speed. You also need to think about what’s going into the tablets. Some powders are easy to press into tablets. Others are tricky and need special handling. It’s like baking – different ingredients need different methods to make the perfect treat.

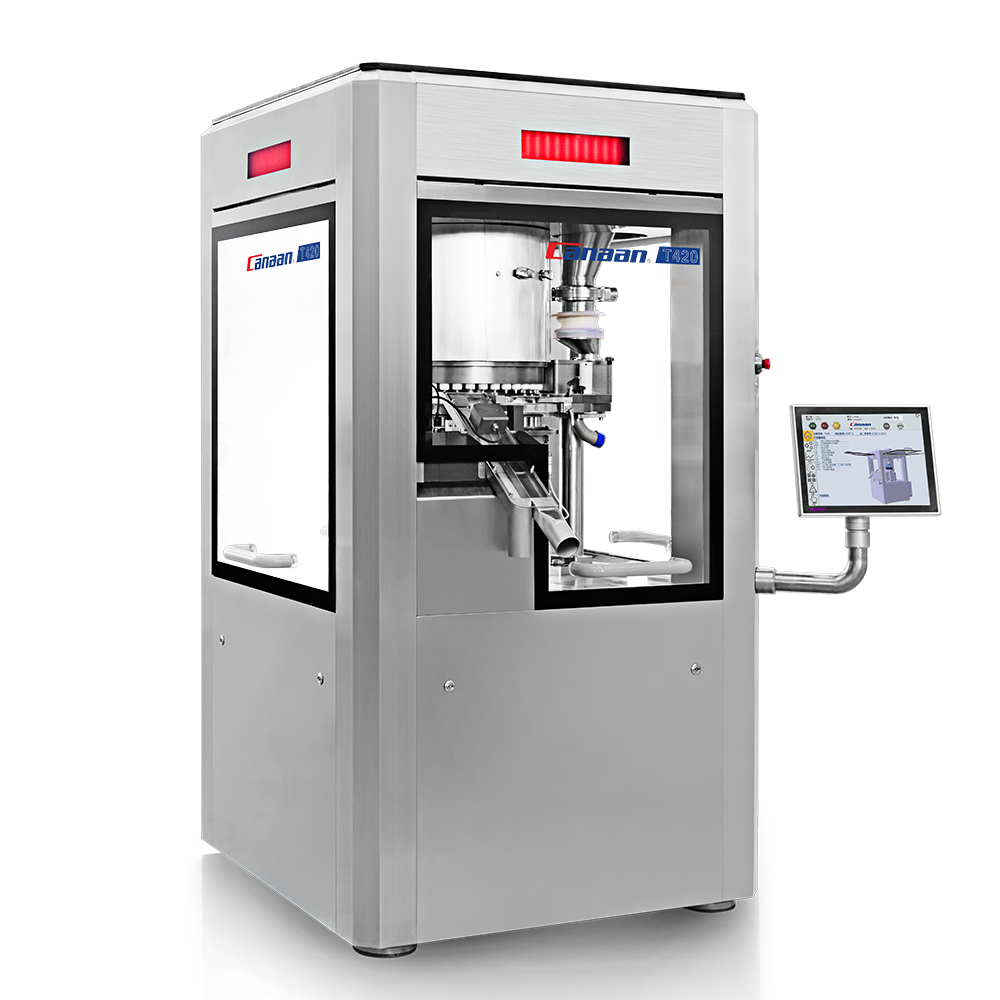

Today’s tablet presses are very high-tech. Many have touch screens and can connect to computers. They collect data about every tablet they make. Some can even predict when they’ll need maintenance, like a car that tells you when it needs an oil change.

These smart features help make sure every tablet is safe and works well. They also help companies make tablets faster and with less waste.

Taking care of a tablet press is very important. These machines work hard and need regular check-ups. Keeping them clean and in good shape helps make sure the tablets are safe and work well.

Safety is also key. Tablet presses have lots of moving parts that can be dangerous. Modern machines have special guards and emergency stop buttons to keep workers safe.

The world of tablet presses keeps changing. Scientists are working on new ways to make tablets even better. Some new ideas include:

Tablet presses have come a long way from simple machines to high-tech wonders. They play a big part in making sure we all have the medicines we need. As we find new ways to make drugs work better, tablet presses will keep changing to meet those needs.

Ready to improve how you make tablets? We have tablet presses for every need, from small batches to millions a day. Talk to our experts and find the perfect tablet press machine or rotary tablet press for you. Don’t wait – make your tablet production better now!

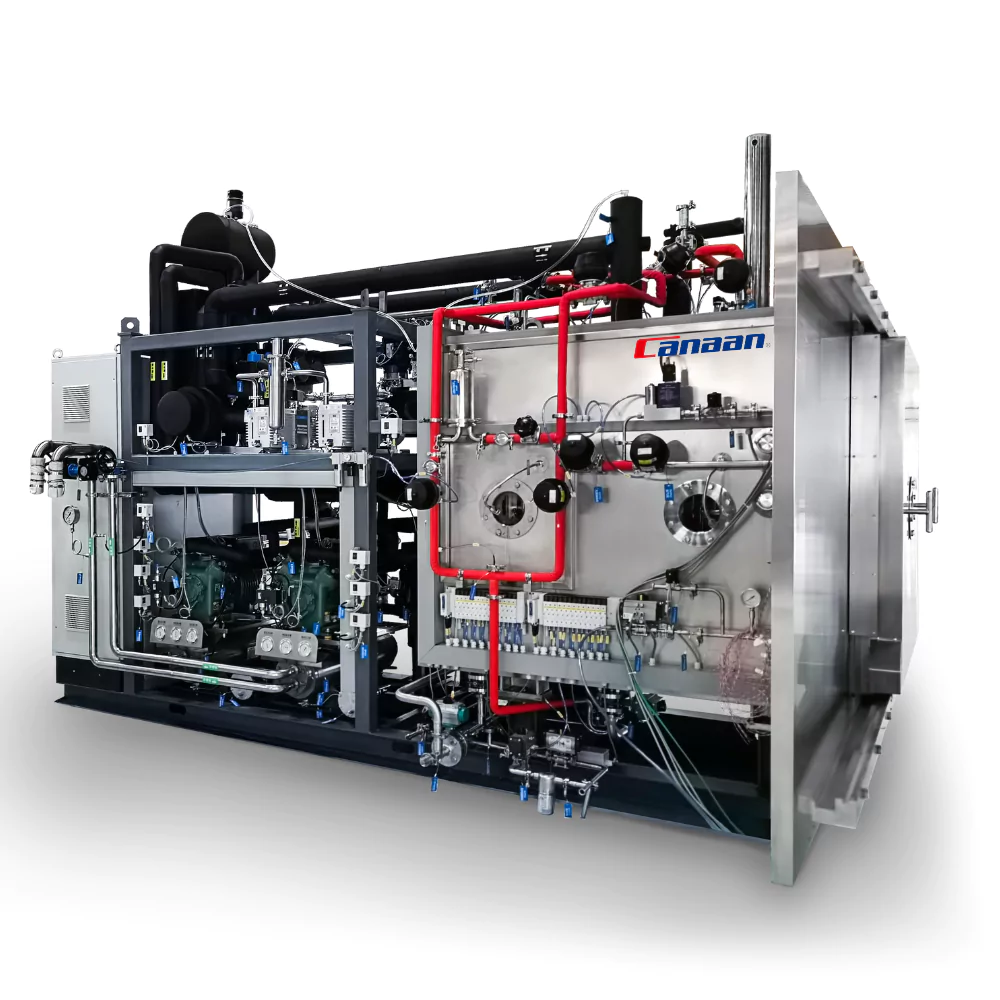

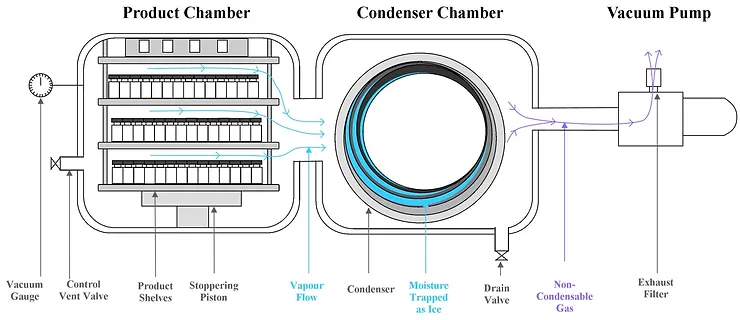

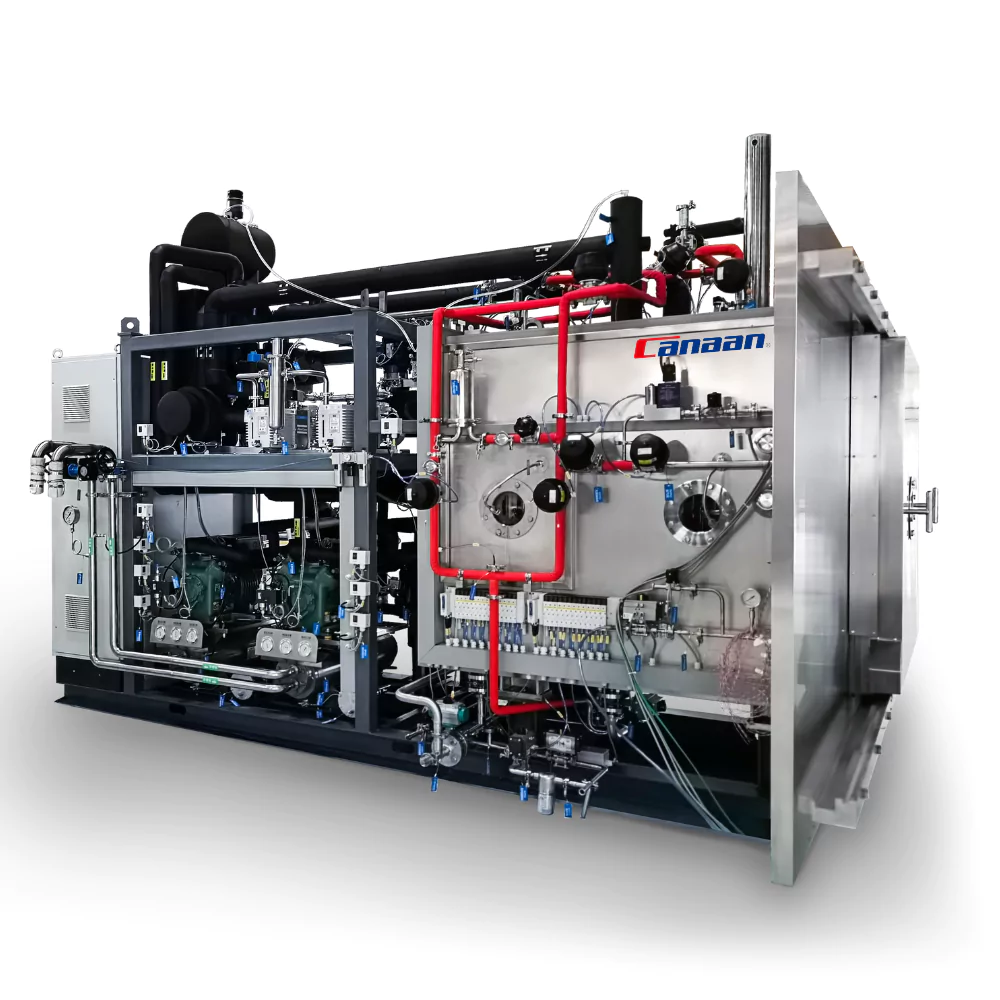

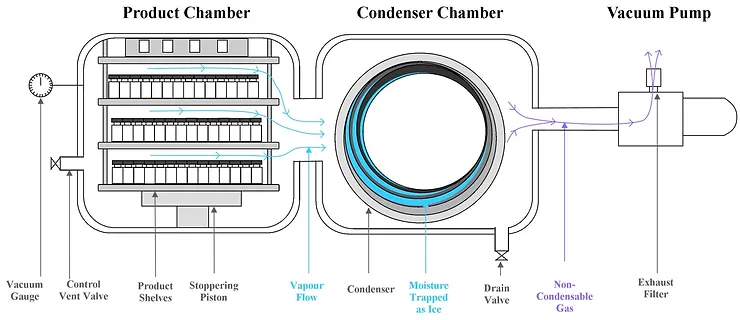

What is lyophilization? Freeze-drying, or lyophilization, is an important process in the pharmaceutical industry. It helps preserve medicines, vaccines, and other sensitive products by removing moisture. If you buy a used freeze-dried machine, it’s essential to take proper care of it. Proper maintenance will extend the machine’s life, improve efficiency, and ensure the safety and […]

What is freeze-drying? Freeze drying, also called lyophilization, is a method used to preserve medicines, vaccines, and other sensitive products. It removes moisture from products, which helps them stay stable for longer. In the pharmaceutical industry, freeze-drying is key to storing important products, like biologics and vaccines, without needing refrigeration. For freeze-drying to work, you […]

In the pharmaceutical industry, two common methods for drying products are freeze-drying and spray-drying. These methods remove water from products like medicines and vaccines, making them last longer and easier to store. But how do they work? And which one is better for different types of products? Let’s explore the differences between freeze-drying and spray-drying, […]