The importance of this material for pharmaceutical industries spans from its high corrosion resistance, which prevents contamination, to being simple to clean and maintain. These ensure your industrial processes will go on without a hitch.

Find out what pharmaceutical stainless steel is and why it should be part of your industry’s routines. This guide tackles the following:

– Overview of pharmaceutical stainless steel

– Types and uses

– Importance of stainless steel for the industry

You are familiar with the material used in cookware and medical instruments, among others. However, stainless steel used in the pharmaceutical industry refers to alloys of iron, chromium, and various other metals working synergistically to craft a passive layer on this steel’s surface, shielding the underlying metal from damage and oxidation.

Industrial factories may also add more elements, such as molybdenum and nickel, in order to improve certain characteristics, including weldability or formability.

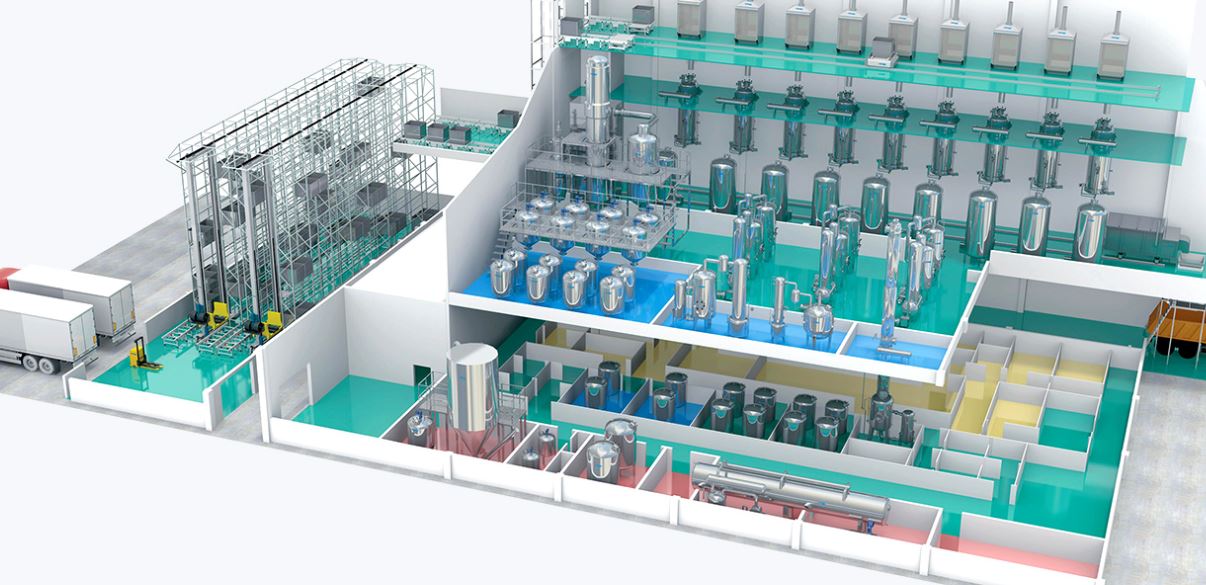

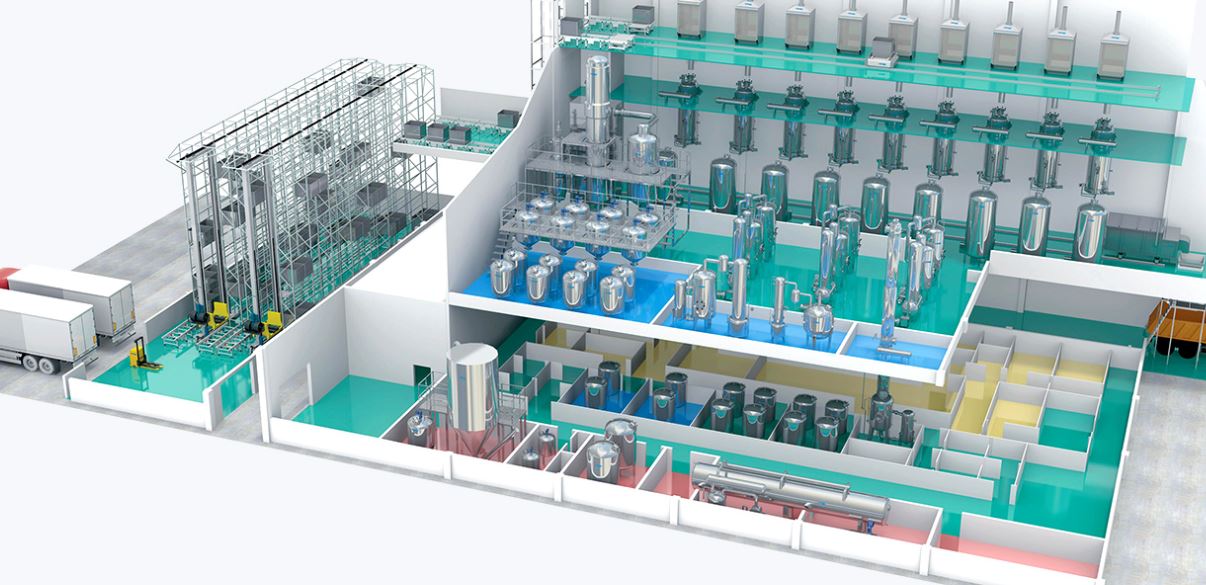

Moreover, its non-reactive properties against most drugs and many other chemicals make it ideal to be used in tanks, pipes, valves, and other equipment during manufacturing processes that need to keep contamination at bay.

This creates a medical grade stainless steel, a corrosion-resistant steel that works exceptionally well for your industry’s purposes.

Here are the most popular types of stainless steel:

The biggest uses of this material in the pharmaceutical industry are:

Below are five reasons why stainless steel is very important in drug manufacturing:

Pharmaceutical stainless steel must resist chemical, fluid, and temperature degradation. To make this possible, the stainless steel’s chromium content works overtime, since pharmaceutical facilities are rife with chemicals and potential cleaning agents.

In producing drugs, there are processes that remove microorganisms, such as autoclaving and sterilization that need materials to withstand extremely high temperatures without degradation Stainless steel equipment are engineered to protect against these demanding conditions, ensuring effective sterilization.

Stainless steel features smooth and non-porous surfaces that prevent the growth of microbes and facilitate easy, thorough cleaning. This is important to prevent contamination and uphold the highest standards in manufacturing drugs.

Furthermore, stainless steel is also intrinsically inert, so it won’t readily react with sensitive pharmaceutical ingredients. With it being non-reactive, unwanted altercations in the drug’s composition are prevented, safeguarding its efficacy, overall stability, and safety.

Simply put, a stainless steel strong for the pharmaceutical industry is longer-lasting. There is minimal need for frequent replacement, thus ensuring consistent performance, cost-effectiveness, and reliability.

There is no question that this is the best choice of material for pharmaceutical equipment. It is resistant to corrosion and high temperatures, easy to clean and maintain, never reactive, and will last longer.

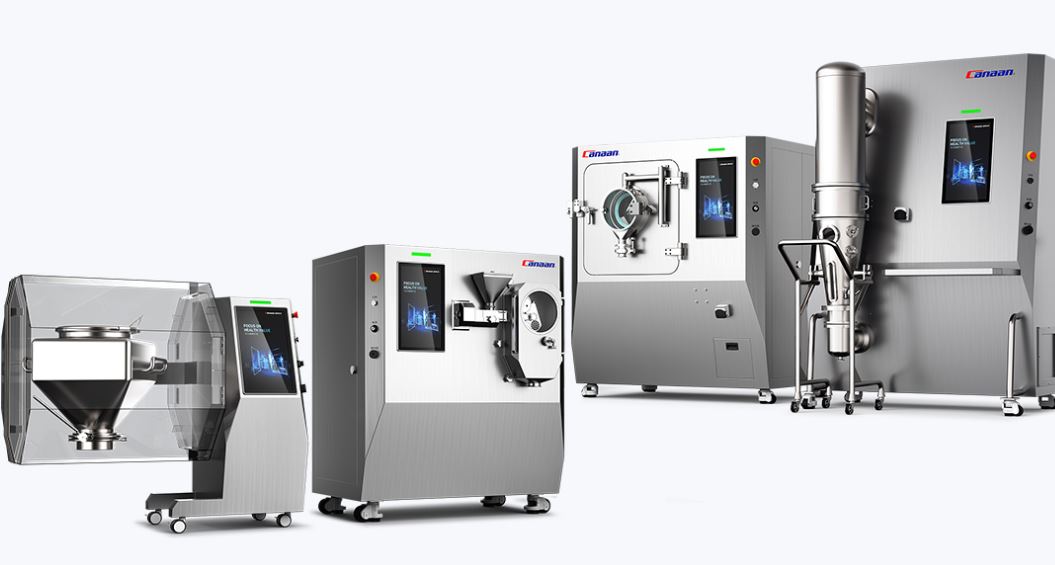

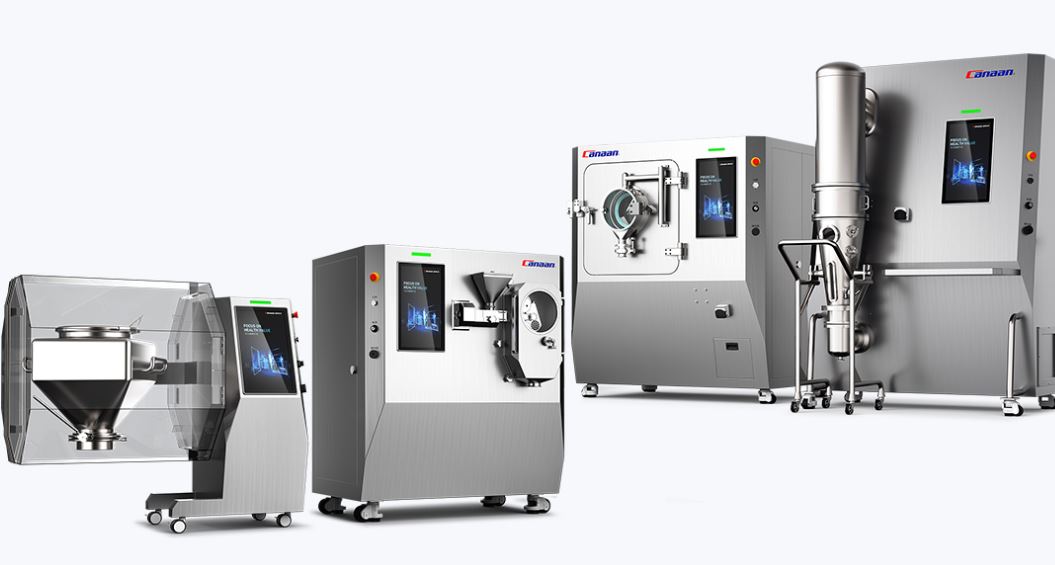

For equipment made with the most top-notch stainless steel, choose to get them from Canaan. Since 2000, it has been providing A-list equipment for its wide range of clientele. Many of its products, such as the IS120/IS240 Desiccant Inserting Machine and MC Series Dust Free Crushing Module feature stainless steel to ensure efficient operations.

Take your pharmaceutical produce to new heights by connecting with Canaan today.

Resources:

The Stainless Steel Solution: Enhancing Pharmaceutical Manufacturing and Research Safety

In producing semaglutide API, or the active pharmaceutical ingredient in the “weight loss magic drug” semaglutide, an agitated nutsche filter dryer becomes effective. This equipment is used to separate the solid parts from the liquid components, before drying them in a vessel. Let’s embark on a journey to understanding more about this equipment, particularly its […]

Pharmacognostic processes are about the study of medicines or drugs made from natural resources, such as plants, animals, and even microbes. This knowledge field involves evaluating the drugs’ chemical, biological, biochemical, and physical properties. To acquire the desired natural products from crude materials in drug manufacturing, extraction is needed. There are six modern methods of […]

Occasionally, blunders on the usage of pharmaceutical equipment can happen. Some of these include improper pharmaceutical maintenance and sanitation, wrongly assuming the equipment meets standards, and failure to replace faulty parts after maintenance. Then, issues on compliance may also be encountered. However, can these be prevented and safety in the pharmaceutical industry ensured? Definitely. This […]