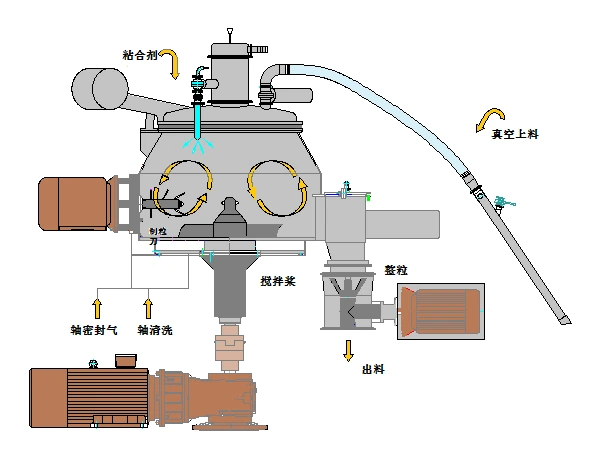

The High Shear Mixer can complete the processes of mixing, binder charging and granulating at one time, and by using impeller, the materials move axially, radially and tangentially in the container, so as to obtain the uniform mixed powder. The mixed powder is combined with binders or wetting agents to form soft materials, then the soft materials are formed as particles after cutting by chopper. Figure 1 shows the operation of high shear mixer. The features of particles prepared by wet granulation are: better surface modification, well-shaped appearance, strong wear resistance, good compression form-ability, etc.

High Shear Mixer is a machine of electricity and gas integrated equipment which applies PLC program control technology and frequency conversion control technology.The wet mixing granulator is an integrated machine, electricity and gas equipment that applies PLC program control technology and frequency conversion control technology. It is suitable for mixing and granulating powdery loose materials in the pharmaceutical, food, chemical and other industries, and can also be used for dry powder mixing.

| Unit | LHS25 | LHS50 | LHS75 | LHS100 | LHS150 | LHS200 | LHS300 | LHS400 | LHS500 | LHS600 | LHS800 | LHS1000 | LHS1200 | LHS1500 | |

| Nominal volume | L | 25 | 50 | 75 | 100 | 150 | 200 | 300 | 400 | 500 | 600 | 800 | 1000 | 1200 | 1500 |

| Feed quantity | L | 10~20 | 20~40 | 30~60 | 40~80 | 60~120 | 80~160 | 120~240 | 160~320 | 200~400 | 240~480 | 320~640 | 400~800 | 480~960 | 600~1200 |

| Impeller power | kW | 2.2 | 4 | 5.5 | 11 | 15 | 18.5 | 22 | 30 | 37 | 45 | 55 | 55 | 75 | 75 |

| Impeller speed | r/min | 20~200 | 20~200 | 20~200 | 20~200 | 15~175 | 15~175 | 15~175 | 15~175 | 15~175 | 15~175 | 10~145 | 10~120 | 10~110 | 10~100 |

| Granulation power | kW | 1.1 | 2.2 | 3 | 4 | 3 | 5.5 | 7.5 | 7.5 | 11 | 11 | 15 | 15 | 18.5 | 2×18.5 |

| Granulation speed | r/min | 1000~2000 | 1000~2000 | 1000~2000 | 1000~2000 | 1000~2000 | 1000~2000 | 1000~2000 | 1000~2000 | 1000~2000 | 1000~2000 | 1000~2000 | 1000~2000 | 1000~2000 | 1000~2000 |

| Mill power | kW | 0.75 | 0.75 | 0.75 | 1.1 | 3 | 3 | 3 | 4 | 4 | 5.5 | 5.5 | 5.5 | 5.5 | 2*5.5 |

| Mill speed | r/min | 300~900 | 300~900 | 300~900 | 300~900 | 300~900 | 300~900 | 300~900 | 300~900 | 300~900 | 300~900 | 300~900 | 300~900 | 300~900 | 300~900 |

| Air consumption | m3/min | 0.4 | 0.4 | 0.4 | 0.4 | 0.6 | 0.6 | 0.6 | 0.6 | 1 | 1 | 1 | 1.5 | 1.5 | 2 |

| Air pressure | MPa | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 |