In the pharmaceutical industry, the process of coating tablets and capsules plays a crucial role in ensuring the safety, effectiveness, and appeal of the final product. Two of the most commonly used coating methods are sugar coating and film coating.

Both methods have their unique characteristics and benefits, but they serve different purposes depending on the drug formulation and patient needs.

This article will explore the key differences between sugar coating and film coating, along with typical scenarios where each type is preferred.

Choose the Right Coating Method for Your Pharmaceuticals

Pharmaceutical coatings protect the drug, mask unpleasant tastes, enhance appearance, and, in some cases, control how the drug is released in the body. By understanding the differences between sugar coating and film coating, pharmaceutical manufacturers can choose the most appropriate method based on the specific requirements of their product.

What is sugar coating? Sugar coating is a more traditional coating method that dates back several centuries. It is primarily used in situations where masking the unpleasant taste or odor of a drug is essential.

The sweet, smooth, and glossy finish that sugar coating provides makes tablets more palatable for patients. This type of coating is also often used when aesthetics play a significant role in patient compliance, particularly for pediatric or geriatric populations.

Sugar-coated tablets are visually appealing, which can help make the medication more acceptable and marketable.

However, sugar coating has its limitations. It significantly increases the size and weight of the tablet, which can be a drawback for patients who struggle with swallowing large tablets. It is also a time-consuming and labor-intensive process, requiring multiple layers to achieve the desired thickness and smoothness.

What is film coating? Film coating, on the other hand, is a modern method widely used in today’s pharmaceutical manufacturing. It is preferred in situations where protection from environmental factors like moisture, light, or air is critical.

Unlike sugar coating, film coating does not significantly increase the size or weight of the tablet, making it easier to swallow and more convenient for patients.

Film coating is also ideal for drugs that require controlled or delayed release. The thin polymer layer used in film coating can be designed to dissolve at specific points in the digestive system, ensuring that the drug is released at the right time and place. This makes film coating more versatile and functional compared to sugar coating, particularly for medications with specific release profiles.

| Aspect | Sugar Coating | Film Coating |

| Appearance | Thick, shiny, and polished finish. Visually appealing with rounded edges. | Thin, matte, or semi-gloss finish. Minimal impact on tablet size or shape. |

| Composition | Sugar-based syrup, often including sucrose, water, and colorants. | Polymer-based solutions, typically using HPMC, ethylcellulose, or PEG. |

| Process | Multi-stage process including sealing, subcoating, coloring, and polishing. | Single-stage process where a polymer film is sprayed and dried in one step. |

| Advantages | Excellent for masking unpleasant tastes and creating an attractive tablet. | Protects from moisture, light, and air. Allows for controlled drug release. |

| Disadvantages | Labor-intensive and time-consuming. Increases tablet size and weight. | May be more expensive. Does not offer the same visual appeal as sugar coating. |

| Typical Use | Over-the-counter drugs, pediatric formulations, or where taste masking is crucial. | Modern pharmaceuticals, controlled-release drugs, and tablets requiring protection. |

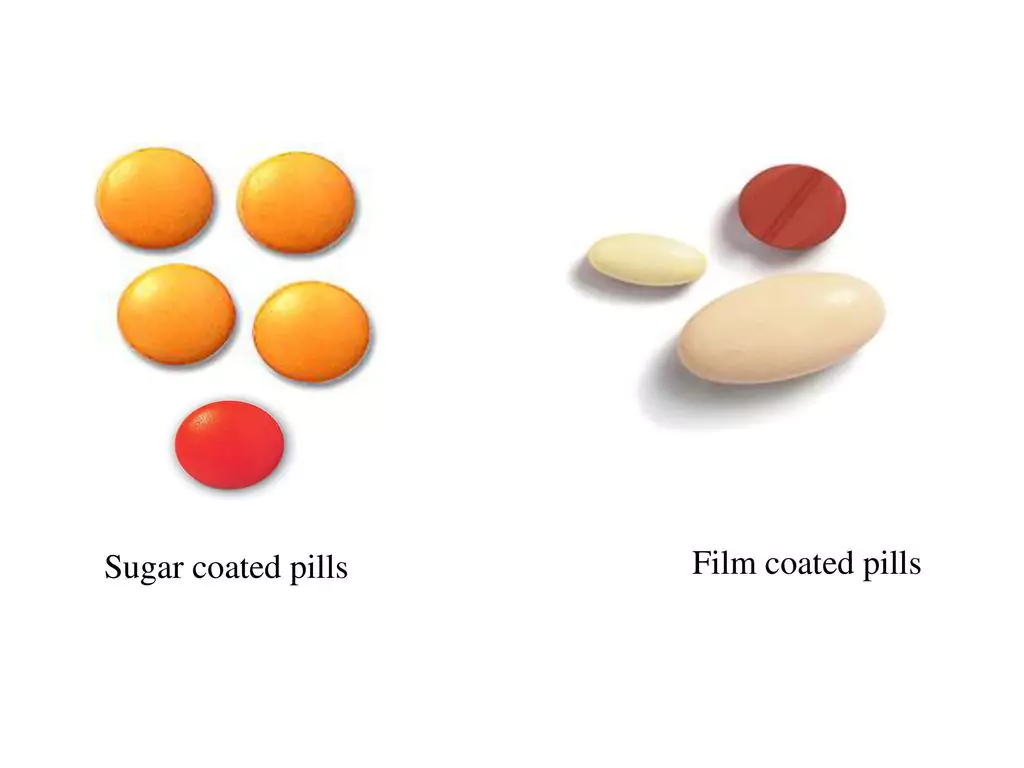

One of the most noticeable differences between sugar coating and film coating is their appearance. Sugar-coated tablets typically have a shiny, polished, and often brightly colored exterior. The coating is smooth and thick, giving the tablet a more rounded and glossy look.

Sugar-coated tablets are visually appealing and are often used for over-the-counter medications where aesthetics can influence consumer choice.

In contrast, film coating results in a much thinner layer that does not alter the shape or size of the tablet significantly. The finish of a film-coated tablet is more matte or semi-gloss, depending on the formulation.

While film-coated tablets may not have the same level of visual appeal as sugar-coated tablets, they are preferred for their functional advantages, such as protection and controlled release.

The composition of the coating materials also differs significantly between the two methods. Sugar coating involves multiple layers of sugar-based syrup that is applied to the tablet. These layers typically include ingredients such as sucrose, water, and sometimes colorants to create the desired appearance and taste.

Film coating, on the other hand, uses a polymer-based solution, which is much thinner than sugar syrup. Common polymers used in film coating include hydroxypropyl methylcellulose (HPMC), ethylcellulose, and polyethylene glycol (PEG).

These polymers form a protective film around the tablet, which can be designed to dissolve at specific points in the gastrointestinal tract. Plasticizers, colorants, and solvents are also added to the solution to enhance the coating’s performance.

The processes for sugar coating and film coating differ in terms of complexity, time, and labor requirements. Sugar coating is a multi-step process that involves several layers, each applied in a different stage. These stages include:

This multi-stage process is labor-intensive and time-consuming, often requiring several hours or even days to complete. It also increases the size and weight of the tablet, making it less practical for modern formulations.

Film coating, by comparison, is a much faster and more efficient process. It typically involves just one layer of polymer solution that is sprayed onto the tablet as it rotates in a coating pan. The process is as follows:

Because film coating only requires a single layer, the process is much quicker and more cost-effective than sugar coating. It also allows for greater control over the thickness and uniformity of the coating, making it ideal for modern pharmaceutical needs.

Would You Like to Know the Difference Between Enteric Coating and Film Coating?

Choosing the right coating method for your pharmaceutical product is crucial for ensuring its efficacy, safety, and appeal. Whether you opt for sugar coating to mask unpleasant tastes and enhance aesthetics or film coating to protect and control drug release, selecting the right equipment and process can make all the difference.

At China Canaan, we offer a range of advanced coating machines designed to meet your manufacturing needs. Our state-of-the-art equipment ensures precision, efficiency, and consistency in every batch.

Contact us today to explore how we can help you optimize your coating process!

Before any drug reaches a patient, it starts in a lab. That’s where formulas are tested, batches are checked, and quality is either confirmed or questioned. To do that work right, labs depend on the right equipment—tools that don’t just get the job done, but do it with precision. If you’re responsible for running or […]

Blister packaging is everywhere in pharma—from tablets to capsules to sample packs. It protects the product, extends shelf life, and improves patient safety. But for manufacturers, it’s more than just packaging—it’s a system built around speed, precision, and compliance. If you’re in pharma manufacturing or packaging procurement, here’s what you need to know about blister […]

If you’re deciding how to deliver a pharmaceutical or supplement product, the format you choose—liquid gels or tablets—will shape more than just how it looks. It affects how the product is made, how fast it’s absorbed, what kind of equipment you’ll need, and how the end user experiences it. Some actives work better in a […]