Coating technology plays an integral role across several industries, especially in pharmaceuticals, where it is critical to ensuring the stability, effectiveness, and patient compliance of drugs.

What are pharmaceutical coatings? Pharmaceutical coatings are protective layers applied to solid dosage forms like tablets and capsules, which offer a range of benefits such as taste masking, extended shelf life, and controlled drug release. The use of coating technology helps enhance both the efficacy and safety of medications.

Coatings are also used in other sectors, including food and electronics, to protect products and improve their functionality.

In this guide, we’ll provide a comprehensive overview of pharmaceutical coating technologies, explore how they are used across different industries, and explain why coating is crucial for medications.

Enhance Efficiency — Order Your Coating Machine Now!

| Industry | Applications |

| Pharmaceutical | – Protects active ingredients from moisture and light. |

| – Enables controlled or sustained drug release. | |

| – Masks unpleasant taste for better consumption. | |

| Food | – Preserves freshness and extends shelf life. |

| – Enhances appearance and flavor (e.g., candy coatings). | |

| – Reduces moisture loss in fruits and vegetables. | |

| Electronics | – Protects circuit boards from moisture, dust, and chemicals. |

| – Prevents water and heat damage in mobile devices. | |

| – Safeguards automotive electronics. |

Coating technology is incredibly versatile and is utilized in several industries to achieve different goals. Let’s explore how coating is applied in various fields:

In the pharmaceutical sector, coating technology is essential for ensuring that medications are safe, effective, and easy to use. Coating plays several critical roles in drug formulation:

Curious How A Coating Machine Works? Discover More Now!

In the food industry, coating technology is applied to preserve food quality, enhance flavor, and extend shelf life. Coatings can protect food products from moisture, oxidation, and spoilage, improving both the appearance and taste. For example:

The use of coatings in the food industry ensures that products remain fresh and visually appealing, contributing to a better consumer experience.

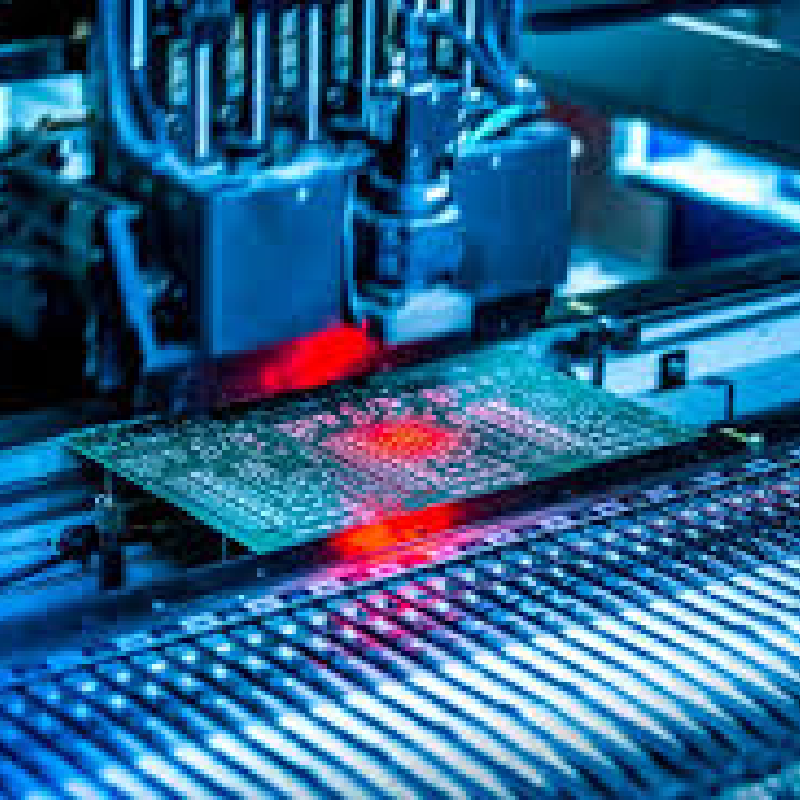

Coating technology is also widely used in the electronics sector to protect sensitive components from environmental exposure. Conformal coatings are applied to circuit boards and other electronic parts to shield them from moisture, dust, and chemicals, ensuring that the components remain functional and reliable even in harsh conditions.

In both consumer and industrial electronics, coatings are crucial for improving durability, performance, and safety.

Coating medications is not just about enhancing their appearance or making them easier to swallow. The coatings serve critical purposes in protecting the drug’s active ingredients, controlling how the drug is released, and ensuring a more pleasant patient experience.

| Reason | Explanation |

| Protection of Active Ingredients | – Shields sensitive drugs from moisture, light, and oxygen. |

| – Preserves efficacy during transport and storage. | |

| Control of Drug Release | – Sustained-release coatings allow gradual drug release, reducing dosing frequency. |

| – Enteric coatings prevent dissolution in the stomach, ensuring release in the intestines. | |

| Taste-Masking | – Masks bitter or unpleasant flavors, improving patient compliance. |

| – Especially important for children, the elderly, or patients on long-term treatments. | |

| Gastrointestinal Protection | – Prevents irritation by ensuring that drugs like NSAIDs dissolve in the intestines, not the stomach. |

Many medications are sensitive to environmental conditions like heat, light, and moisture, which can degrade the drug’s active ingredients and reduce its effectiveness.

Pharmaceutical coatings protect the medication by creating a barrier that shields it from these harmful factors. This is particularly important for medications that need a long shelf life or are exposed to harsh conditions during transport and storage.

For example, some vitamins and enzyme-based medications are highly sensitive to moisture and would lose their efficacy without a protective coating. Similarly, drugs that are prone to oxidation need a coating to prevent degradation when exposed to air.

Coating technology also plays a crucial role in controlling the release of a drug. Different coatings are formulated to release the drug at different times or in specific parts of the digestive system. This is particularly important for:

These coatings enable pharmaceutical companies to design medications that meet the specific therapeutic needs of patients, offering better control over how and when drugs are absorbed by the body.

Some medications have a bitter or unpleasant taste that can make them difficult for patients to tolerate, especially for children, the elderly, or patients who need to take the drug regularly. Pharmaceutical coatings can effectively mask these flavors, making the medication more palatable.

For example, antibiotics often have a strong, bitter taste, which can make it hard for children to take them. By applying a taste-masking coating, the bitterness is masked, and the medication becomes easier to swallow. This leads to better patient compliance, which is critical for the effectiveness of the treatment.

Certain medications, like aspirin and other NSAIDs, can cause irritation or discomfort in the stomach lining. Pharmaceutical coatings, particularly enteric coatings, are designed to prevent the drug from dissolving in the stomach. Instead, these coatings ensure that the drug remains intact until it reaches the intestines, where it can be absorbed without causing irritation.

This is especially important for drugs that are taken long-term or in high doses, as chronic exposure to stomach acid can lead to ulcers and other gastrointestinal issues. By protecting the stomach lining, enteric coatings improve patient comfort and reduce the risk of complications.

At China Canaan, we understand the importance of coating technology in delivering effective, safe, and patient-friendly pharmaceutical products. Whether you need to protect sensitive active ingredients, control the release of the drug, or improve patient compliance through taste masking, our pharmaceutical coating solutions are designed to meet your needs.

Our advanced coating systems ensure precision, consistency, and efficiency in every batch, helping you optimize your manufacturing process and enhance your product’s performance.

If you’re ready to elevate your pharmaceutical production line, contact us to learn more about our state-of-the-art coating technologies and how they can benefit your business.

Manufacturing pharmaceutical products should always be taken seriously. That is, every process must follow the strictest and highest standards. This is the very reason why manufacturers prefer hiring an EPC contractor. Contractors working under EPC contracts will ensure the outcomes are of the best quality no matter what happens, focusing on the construction of the […]

Explore the importance of EPC contracts in pharmaceutical manufacturing. Learn how EPC works, its benefits, and why choosing an EPC contractor can guarantee project success with Canaan’s industry-leading equipment.

Discover how SCADA and PLC improve automation in the pharmaceutical industry. Learn their roles, benefits, and how Canaan’s advanced technology enhances efficiency and safety.