Imagine a method that turns a bunch of powder into perfect, easy-to-handle granules. That’s fluid bed granulation in a nutshell.

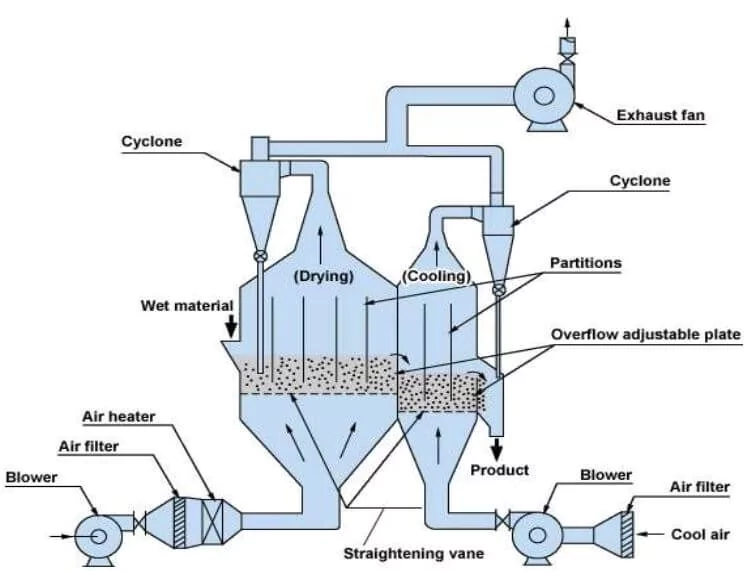

What is fluid bed granulation? Fluid bed granulation is when fine powder is suspended in hot air, creating something almost like a fluid. Then, a binding agent is sprayed onto this “fluidized” powder, causing the particles to stick together and form granules.

The process is incredibly effective for industries like pharmaceuticals, food, and chemicals that need consistent, high-quality granules for their products. But why is this process such a game changer? Let’s dig a little deeper.

Fluid bed granulation wasn’t always the go-to method for granule formation.

In the past, wet granulation was a common technique, where powders were mixed with liquid and later dried in separate steps. This method was time-consuming and prone to inconsistencies.

In the 1960s, with advancements in technology and the increasing demand for more efficient manufacturing processes, fluid bed granulators became popular in the pharmaceutical industry. The ability to combine granulation and drying in one step not only improved efficiency but also ensured uniform particle size—a game-changer for industries relying on precision.

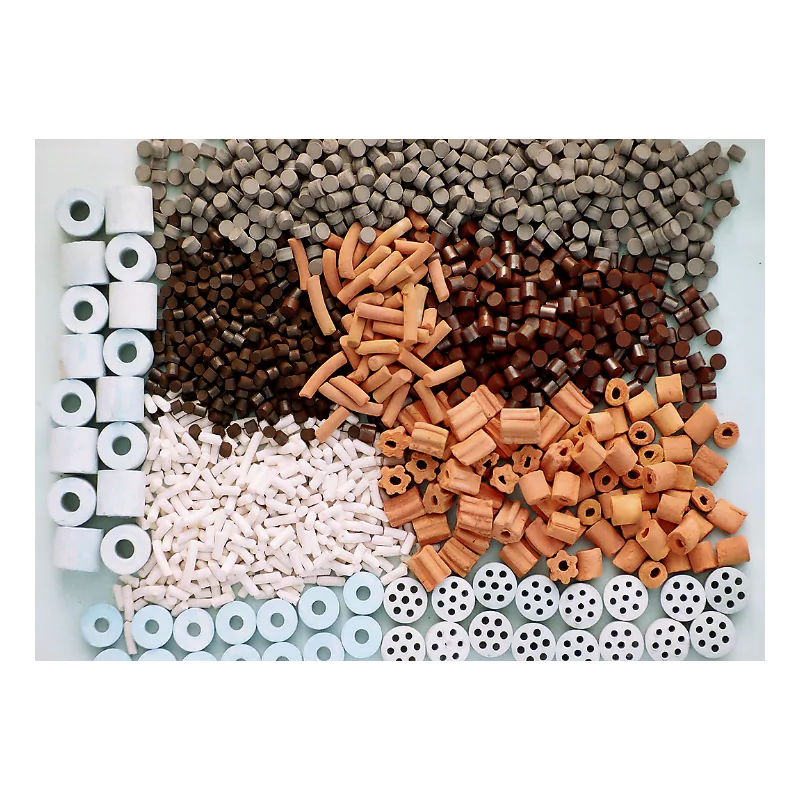

Fluid bed granulation is particularly crucial in pharmaceutical manufacturing. Imagine you’re producing a batch of tablets. You need each tablet to have the same amount of active ingredient and binders, and the powder must flow smoothly through the machines. Fluid bed granulators create consistent, uniform granules that ensure each tablet contains the correct dosage. Moreover, they improve the flow properties of powders, making tablet compression more efficient.

Granules made using this method also dissolve more uniformly, which is essential for medications, especially controlled-release formulas, to work as intended.

In the food industry, fluid bed granulation plays a key role in products like instant coffee, powdered milk, and flavoring agents. It helps create granules that dissolve quickly and evenly in liquids, enhancing the consumer experience. The process also improves the shelf life of these products by reducing moisture content, making them more resistant to spoilage.

Fluid bed granulation is commonly used to manufacture nutraceuticals and dietary supplements. For instance, vitamin tablets or protein powders require even distribution of nutrients to ensure each dose delivers the promised benefits. The granulation process creates uniform granules, which means better stability, controlled release, and improved taste and texture for these supplements.

The chemical industry also benefits from fluid bed granulators. The process is used to create uniform particles in products like catalysts, pigments, and detergents. The uniformity of the granules ensures that chemical reactions happen as expected, improving the efficiency of processes in industries like agriculture, manufacturing, and energy.

| Advantage | Description |

| Efficiency | Combines granulation and drying, saving time and costs. Reduces machine clogs and downtime. |

| Control | Allows precise adjustments of airflow, temperature, and binder, ensuring product quality. |

| Scalability | Easily scales from small batches to large production without changing equipment. |

| Uniformity | Ensures consistent size, weight, and density of granules, ideal for further processing. |

One of the standout benefits of fluid bed granulation is its efficiency. Instead of using separate equipment for granulation and drying, this process combines both steps, cutting down on production time. This efficiency makes it the go-to choice in high-volume manufacturing environments where saving time also means saving money.

Since the process also improves particle flow, machines operate more smoothly, reducing the risk of clogs and downtime.

Another key advantage is the level of control you have over the entire process. Operators can adjust variables like airflow, temperature, and the amount of binder solution to fine-tune the size, moisture content, and density of the granules. This flexibility is a significant asset in industries where consistency and quality are paramount—especially pharmaceuticals, where even the smallest variation in a tablet’s formulation can affect its efficacy.

Whether you’re a small operation or a large-scale manufacturer, fluid bed granulation is easily scalable. You can start with small batches in the research and development phase and later ramp up production using the same equipment. This flexibility makes it an ideal choice for companies looking to expand their operations without needing to overhaul their entire process setup.

Uniformity is crucial when producing granules for pharmaceutical products, food additives, or chemicals. The fluid bed granulator ensures that every particle gets the same exposure to the binder solution and drying air. This results in granules that are not only consistent in size but also in weight and density—making them ideal for further processing, whether it’s tablet compression, capsule filling, or packaging.

Maintaining your fluid bed granulator is vital for ensuring the machine runs smoothly and produces high-quality granules consistently. A well-maintained machine reduces downtime, extends the equipment’s life, and prevents contamination—a critical concern, especially in the pharmaceutical and food industries.

Here’s a simple breakdown of the steps involved in fluid bed granulator maintenance:

At China Canaan, we understand the importance of keeping your fluid bed granulator in top shape. That’s why we offer flexible maintenance services tailored to your needs.

| Service Type | Description |

| Remote Maintenance | Online help for minor issues and quick fixes. |

| On-Site Maintenance | Technicians visit for repairs and emergencies. |

| Local Service Teams | Local teams handle regular maintenance and repairs. |

Our team is available to assist you remotely, diagnosing and troubleshooting issues via online tools. This is especially helpful for minor issues or quick software fixes, saving you time and money.

For more complex problems, we offer on-site maintenance services. Our team will visit your facility, perform repairs, and ensure your machine is running smoothly. We offer both scheduled maintenance and emergency services.

We’ve partnered with local service providers to ensure fast, reliable support in your region. These teams are equipped to handle routine maintenance, emergency repairs, and part replacements, minimizing downtime and keeping your production line running.

If you’re looking to improve your production process, a fluid bed granulator might be the key.

At China Canaan, we offer cutting-edge solutions that ensure consistent, high-quality granulation. Whether you’re in the pharmaceutical, food, or chemical industries, our machines are built to meet your needs.

Contact us today to learn more about our fluid bed granulators and how they can optimize your production.

Manufacturing pharmaceutical products should always be taken seriously. That is, every process must follow the strictest and highest standards. This is the very reason why manufacturers prefer hiring an EPC contractor. Contractors working under EPC contracts will ensure the outcomes are of the best quality no matter what happens, focusing on the construction of the […]

Explore the importance of EPC contracts in pharmaceutical manufacturing. Learn how EPC works, its benefits, and why choosing an EPC contractor can guarantee project success with Canaan’s industry-leading equipment.

Discover how SCADA and PLC improve automation in the pharmaceutical industry. Learn their roles, benefits, and how Canaan’s advanced technology enhances efficiency and safety.