Fluid bed granulation is a widely used process across various industries, especially in pharmaceuticals, chemicals, and food production. This process transforms fine powders into uniform granules, making materials easier to handle and more suitable for downstream processing, such as tableting or capsule filling.

The importance of fluid bed granulation cannot be overstated—it ensures the uniform distribution of active pharmaceutical ingredients (APIs) in medications, leading to accurate dosing and high product quality.

In the food industry, fluid bed granulation is used to create granulated ingredients with improved handling and shelf life. Whether in pharmaceutical, chemical, or food processing, fluid bed granulation has become a cornerstone technique for producing high-quality, reliable products.

In this article, we’ll take a deep dive into how fluid bed granulators work, the essential components involved, and the specific steps in the granulation process, with a special focus on China Canaan’s advanced fluid bed granulation technology.

Connect To Our Fluid Bed Granulator Expert Today!

| Component | Description |

| Air Distributor | Ensures even distribution of heated air for consistent fluidization of the material. |

| Product Container | Holds the powder or material, designed for optimal fluidization to promote granule formation. |

| Spray Nozzle | Introduces the granulating liquid (binder solution) to agglomerate powder particles into granules. |

| Filtration System | Captures airborne particles, preventing material loss and returning them to the product container. |

| Inlet Air Heater | Raises the temperature of incoming air for efficient drying during the granulation process. |

A fluid bed granulator is an intricate piece of equipment designed to execute the granulation process efficiently. It consists of several critical components that work together to ensure the fluid bed granulation process operates smoothly:

What’s the fluidized bed granulation process? The fluid bed granulation process can be broken down into three main stages: fluidization, spraying, and drying. Each stage is vital to ensure the production of uniform, high-quality granules.

| Stage | Description |

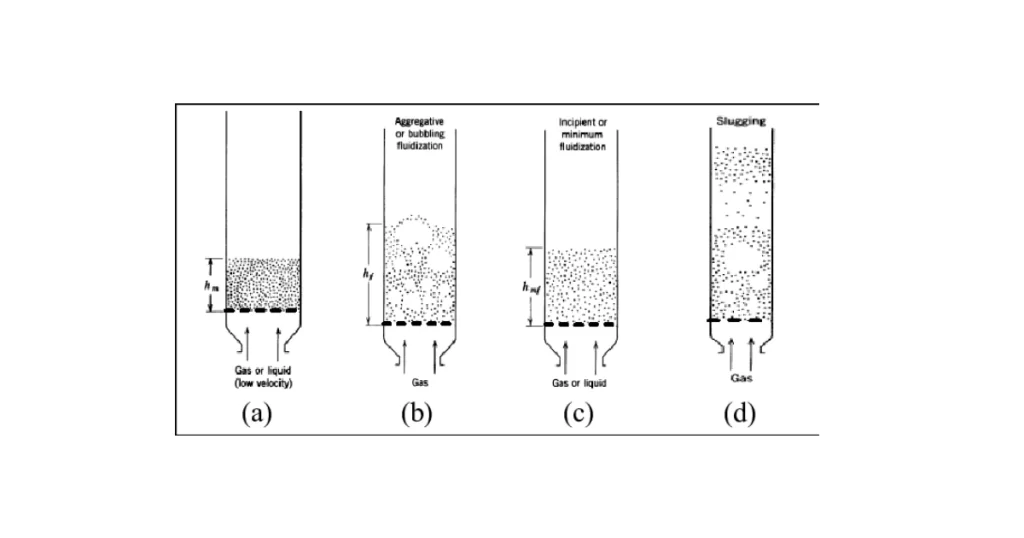

| Fluidization | Heated air is forced into the product container, causing powder particles to become suspended, ensuring even distribution and mixing. |

| Spraying | A granulating liquid is sprayed over the fluidized particles, binding them together to form granules. The liquid choice varies based on the material. |

| Drying | Heated air continues to flow, evaporating the granulation liquid and solidifying the granules into dry, free-flowing particles. |

Step-by-Step Process

This three-stage process—fluidization, spraying, and drying—occurs within a single unit, making fluid bed granulation highly efficient. The ability to complete all these steps in one piece of equipment significantly reduces processing time and labor costs, while also minimizing material loss due to handling.

Fluid bed granulation is versatile and can be used with a wide variety of materials. In the pharmaceutical industry, it is often employed for processing powders containing active pharmaceutical ingredients (APIs), which require precise control over particle size and consistency.

The food industry uses fluid bed granulation to process ingredients like powdered sugar, milk powder, and other fine particles that benefit from being converted into granules for easier handling and extended shelf life.

Additionally, the chemical industry utilizes fluid bed granulation to create uniform granules from fine powders that may otherwise be difficult to handle. Materials that are heat-sensitive or prone to degradation also benefit from fluid bed granulation, as the process can be tailored to prevent overheating and product degradation.

China Canaan, a global leader in pharmaceutical equipment manufacturing, is at the forefront of innovation in fluid bed granulation technology.

Our fluid bed granulators are engineered to provide consistent, high-quality granulation results, ensuring that materials are uniformly processed with minimal waste. China Canaan’s machines are designed with the latest technological advancements, offering superior performance in both large-scale and small-scale production environments.

| Feature | Description |

| High Efficiency | Fast processing reduces batch production time and material loss. |

| Consistency | Ensures uniform granule size with real-time control for batch consistency. |

| Energy Efficiency | Optimized design lowers operational costs while maintaining quality. |

| Versatility | Customizable for various materials and granulating liquids, suitable for different production scales. |

China Canaan’s fluid bed granulators are designed for fast processing, allowing manufacturers to produce large batches of granulated materials in shorter timeframes. The streamlined design reduces material handling and minimizes product loss.

Our machines guarantee uniform granule size, which is essential in industries like pharmaceuticals, where precise dosage forms are critical. The real-time control systems ensure that the process remains consistent from batch to batch.

With rising energy costs, efficiency is more important than ever. China Canaan’s fluid bed granulators are designed to optimize energy use, reducing operational costs without compromising on quality.

Whether you need to granulate heat-sensitive materials or more robust powders, China Canaan’s fluid bed granulators can be customized to handle a wide range of products. Our machines offer flexibility, accommodating different granulating liquids, material types, and production scales.

Ready to upgrade your granulation process?

Contact us today to learn more about our advanced fluid bed granulation systems and how they can benefit your business. Our team of experts is here to help you find the right solution to meet your production goals. Let us help you take your manufacturing capabilities to the next level.

Manufacturing pharmaceutical products should always be taken seriously. That is, every process must follow the strictest and highest standards. This is the very reason why manufacturers prefer hiring an EPC contractor. Contractors working under EPC contracts will ensure the outcomes are of the best quality no matter what happens, focusing on the construction of the […]

Explore the importance of EPC contracts in pharmaceutical manufacturing. Learn how EPC works, its benefits, and why choosing an EPC contractor can guarantee project success with Canaan’s industry-leading equipment.

Discover how SCADA and PLC improve automation in the pharmaceutical industry. Learn their roles, benefits, and how Canaan’s advanced technology enhances efficiency and safety.