First, what is lyophilization? Lyophilization, or freeze-drying, is a process that preserves medicines, food, and other products. It’s used to remove moisture from products while keeping them intact.

Temperature plays a very important role in this process. If the temperature is not right, the product could be ruined.

In lyophilization, the product is frozen, dried, and then finished drying. The temperature needs to be controlled at each stage. This helps to preserve the product and keep it safe for long periods.

This article will explain what temperature is needed for each stage of lyophilization. We will also talk about why temperature control is so important.

In need of a high-performance and dependable Lyophilization machine?

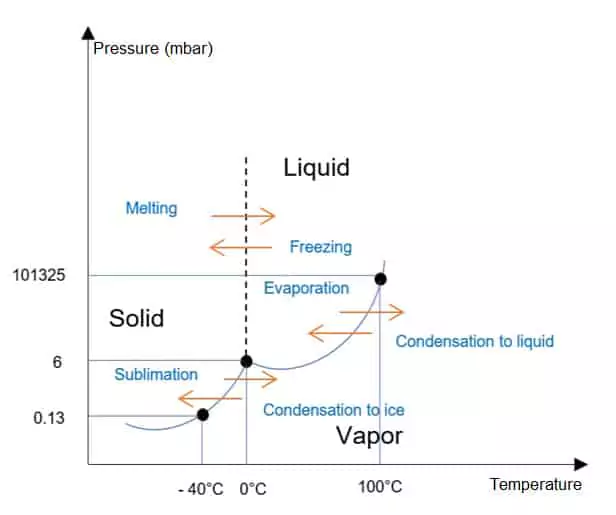

Lyophilization works by removing water from a product. First, the product is frozen solid. Then, the frozen water turns into vapor and leaves the product. This keeps the product dry and helps it stay fresh for longer.

Temperature is very important in this process. It must be just right. If the temperature is too high, the product could be ruined. If it is too low, the product might not dry properly.

Temperature control helps preserve the product’s strength. This is very important for medicines and vaccines, which need to be stored safely. Lyophilization helps make sure that products can be stored for long periods without refrigeration.

Temperature control in lyophilization is key to keeping the product stable. If the temperature is too high, it could cause the product to break down. For example, a vaccine might lose its effectiveness if the temperature is too high during lyophilization.

If the temperature is too low, the product may not dry properly. This could cause some moisture to stay in the product, which could make it unstable. Lyophilization works best when the temperature is controlled carefully.

When the temperature is controlled the right way, the product remains stable and safe. This ensures the product’s effectiveness, whether it is a vaccine, medicine, or another sensitive product.

Lyophilization has three main stages. The temperature is different in each stage. Let’s take a look at the temperature for each stage.

| Stage | Temperature Range | Purpose |

| Freezing Stage | -40°C to -80°C (-40°F to -112°F) | Freeze the product completely before drying. |

| Primary Drying | -20°C to -40°C (-4°F to -40°F) | Remove most water by turning frozen water into vapor. |

| Secondary Drying | 20°C to 30°C (68°F to 86°F) | Remove remaining moisture and stabilize the product. |

| Final Drying | 20°C to 30°C (68°F to 86°F) | Remove the last bit of moisture for stable storage. |

In the freezing stage, the product is frozen. The temperature is very low to make sure the product is completely frozen. The freezing temperature is usually between -40°C and -80°C (-40°F to -112°F). This prepares the product for drying.

During the primary drying stage, most of the water is removed from the product. The temperature is raised a little bit during this stage, usually between -20°C and -40°C (-4°F to -40°F). This helps the frozen water turn into vapor. As the water leaves, the product stays solid and intact.

The next stage is secondary drying. In this stage, the remaining moisture is removed from the product. The temperature is raised even higher, usually between 20°C and 30°C (68°F to 86°F). This ensures the product is completely dry and stable for storage.

After primary drying, there is still a small amount of moisture left. The final drying stage removes this last bit of moisture. The temperature is raised to between 20°C and 30°C (68°F to 86°F) during this stage. This step makes sure the product is completely dry and stable for storage.

Temperature control during lyophilization is very important for product quality. If the temperature is too high, it could destroy the product’s active ingredients. This could make the product less effective or even dangerous to use.

If the temperature is too low, it could prevent the product from drying properly. Some moisture could remain in the product, which could cause it to break down over time. Temperature control ensures that the product is dried properly and remains effective.

By keeping the temperature at the right level, lyophilization helps preserve medicines and other products. This helps ensure the product remains effective and safe for longer periods. For example, vaccines need to stay at the correct temperature to remain useful.

Temperature control in lyophilization can be difficult. Small changes in temperature can have big effects. For example, if the temperature is too high during primary drying, it could cause the product to melt. If it is too low, the product may not dry properly.

Manufacturers need good equipment to control the temperature. The equipment must be able to monitor the temperature closely and adjust it as needed. This is important to make sure that the product is not ruined during the process.

Technology has made it easier to control the temperature during lyophilization. Modern lyophilizers come with sensors that measure the temperature in real time. These sensors can adjust the temperature automatically to make sure it stays at the correct level.

These advancements help make the process faster and more accurate. New lyophilizers also help save time and money. With better equipment, temperature control is more efficient and effective.

As technology continues to improve, lyophilization will become even more efficient. In the future, we can expect even more precise control over the temperature, which will lead to better product preservation.

Temperature control is one of the most important parts of lyophilization. It helps preserve the product and ensures it stays effective. By controlling the temperature during each stage—freezing, primary drying, and secondary drying—manufacturers can make sure the product is safe and stable.

If you are looking for reliable equipment to improve your lyophilization process, Canaan has high-quality solutions. Our equipment helps control the temperature accurately and preserve your products. Learn more about our products by visiting our website or getting in touch with us.

Discover all of Canaan’s high-performance Lyophilization machines.

Manufacturing pharmaceutical products should always be taken seriously. That is, every process must follow the strictest and highest standards. This is the very reason why manufacturers prefer hiring an EPC contractor. Contractors working under EPC contracts will ensure the outcomes are of the best quality no matter what happens, focusing on the construction of the […]

Explore the importance of EPC contracts in pharmaceutical manufacturing. Learn how EPC works, its benefits, and why choosing an EPC contractor can guarantee project success with Canaan’s industry-leading equipment.

Discover how SCADA and PLC improve automation in the pharmaceutical industry. Learn their roles, benefits, and how Canaan’s advanced technology enhances efficiency and safety.