Dry granulation is a vital process across various industries, including pharmaceuticals, chemicals, and food production. It allows for the formation of granules without requiring a liquid binder, making it an essential method for moisture-sensitive materials.

The two main techniques used for dry granulation are slugging granulation and roller compaction. While both methods achieve the same goal—producing granules from powder—they differ in process and application.

Ready to Choose the Right Dry Granulation Methode?

What is dry granulation? Dry granulation is a process where powder particles are made to adhere to one another without the use of liquid binders. This technique is often used when the material is sensitive to heat or moisture, as no liquid is introduced.

This method can be performed using either slugging or roller compaction, each offering its advantages depending on the production requirements.

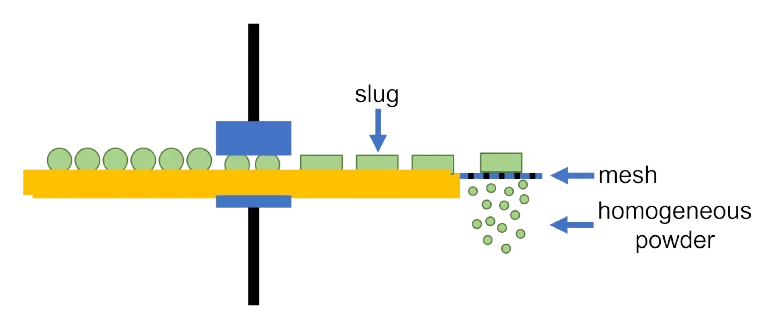

What is slugging granulation? Slugging granulation is one of the oldest methods of dry granulation. In this process, powders are compressed into large tablets or “slugs” using a conventional tablet press. Once the slugs are formed, they are milled or broken down into smaller granules of the desired size. The process involves high pressure, which helps form large, compact slugs from powder.

While slugging is cost-effective and requires minimal equipment, it tends to be less precise in controlling the size and uniformity of the granules. This method works best for smaller-scale operations and materials that are not sensitive to the pressure used during the slugging process.

A powder blend is prepared by mixing the active ingredients and excipients.

The powder is fed into a tablet press, where it is compressed at high pressure into large slugs, typically 25 mm in diameter and 10-15 mm thick.

The slugs are broken down into granules using a mill.

Granules are screened to ensure they meet the desired particle size, and any oversized particles are recycled back into the process.

Simple and cost-effective process

Minimal equipment requirements

Suitable for smaller production runs

Inconsistent granule size

Not ideal for large-scale production

High variability in slug weight, which can affect granule properties

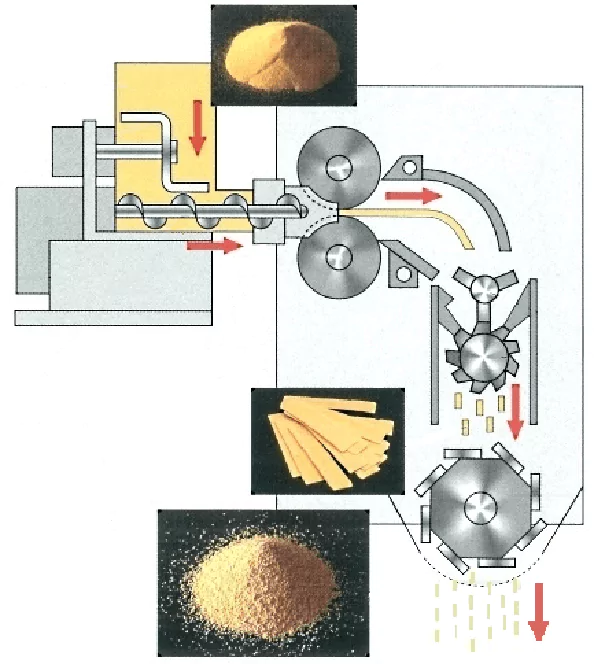

What is roller compaction? Roller compaction is a more advanced and precise method of dry granulation. In this process, the powder is passed through two counter-rotating rollers, where it is compressed into thin ribbons or flakes. These ribbons are then milled to form granules of the desired size.

A roller compactor offers more control over the density and size of the granules, making it ideal for large-scale production where consistency is crucial.

Unlike slugging, roller compaction allows for continuous production, making it more efficient for high-volume operations. It is also better suited for sensitive materials that cannot withstand the high pressures used in slugging.

The powder is fed into the machine through a hopper and moved toward the rollers using either an auger or gravity feed.

The powder is compressed between two counter-rotating rollers, forming thin ribbons or sheets.

The ribbons are broken down into granules using a milling system.

The granules are screened to ensure they meet the desired size and shape, and any fine particles are recycled back into the process for re-compaction.

Greater control over granule size and density

Continuous production process

Ideal for large-scale operations

Suitable for sensitive materials that require gentle handling

Requires more advanced and expensive equipment

Higher initial setup costs compared to slugging

Not as cost-effective for small-scale operations

| Method | Advantages | Disadvantages |

| Slugging Granulation | Simple and cost-effective process | Inconsistent granule size |

| Minimal equipment requirements | Not ideal for large-scale production | |

| Suitable for smaller production runs | High variability in slug weight, affecting granule properties | |

| Roller Compaction | Greater control over granule size and density | Requires more advanced and expensive equipment |

| Continuous production process | Higher initial setup costs compared to slugging | |

| Ideal for large-scale operations | Not as cost-effective for small-scale operations | |

| Suitable for sensitive materials that require gentle handling | / |

When comparing slugging and roller compaction, it’s essential to consider the scale of production, the material being processed, and the desired granule properties.

Slugging is more suitable for smaller production runs due to its simplicity and lower cost. Roller compaction, on the other hand, is designed for large-scale operations where precision and consistency are critical.

Roller compaction provides better control over granule size, density, and uniformity. Slugging can produce more variability in these factors, which may not be suitable for high-precision industries like pharmaceuticals.

Slugging requires a simple tablet press, while roller compaction involves more complex machinery, including a roller compactor and milling system. As a result, roller compaction has higher initial equipment costs but offers greater scalability.

Slugging vs Roller Compaction Table:

| Criteria | Slugging Granulation | Roller Compaction |

| Process | Compresses powder into large slugs, which are then milled into granules | Compresses powder between two rollers, then mills ribbons into granules |

| Precision | Lower control over granule size and uniformity | Higher precision with better control over granule size and density |

| Production Scale | Best suited for small-scale production | Ideal for large-scale, continuous production |

| Equipment | Requires a simple tablet press and milling system | Requires advanced equipment, including roller compactor and milling system |

| Cost | Lower initial cost, minimal equipment needed | Higher initial setup cost due to complex machinery |

| Granule Quality | Inconsistent granule size and weight | Consistent granule size, density, and uniformity |

| Suitability for Sensitive Materials | Not ideal for heat- or pressure-sensitive materials | Suitable for handling sensitive materials requiring precise control |

| Applications | Used for smaller batches or materials that can tolerate higher pressure | Preferred for large-scale operations in pharmaceuticals, chemicals, and food industries |

Both slugging and roller compaction are used across various industries, but their applications differ depending on the specific needs of the production process.

In the pharmaceutical sector, roller compaction is often the preferred method due to its ability to produce consistent, high-quality granules. This is particularly important for drugs that require precise dosing and uniformity in tablet form. Slugging may still be used for small-batch production or for materials that can withstand higher pressures.

The chemical industry often uses roller compaction for large-scale production of chemicals and fertilizers. The ability to control the density and size of granules is critical for ensuring product quality and ease of handling.

Dry granulation is used in the food industry to produce granules for products such as instant drinks, flavorings, and dietary supplements. Roller compaction is typically preferred for its precision, especially when dealing with sensitive ingredients.

Choosing between slugging granulation and roller compaction depends on several factors, including the scale of production, the sensitivity of the material, and the level of precision required.

Slugging offers a cost-effective solution for smaller-scale production, while roller compaction provides greater control and efficiency for large-scale operations.

If you are looking for a reliable, scalable solution for your dry granulation needs, roller compactor technology from China Canaan is an excellent choice. Our advanced machinery ensures consistent, high-quality granules while optimizing your production efficiency.

At China Canaan, we specialize in cutting-edge roller compaction technology that caters to the needs of various industries, including pharmaceuticals, chemicals, and food production.

Our roller compactor machines are designed to offer superior control, consistency, and efficiency, ensuring that your production process runs smoothly from start to finish.

Whether you’re looking to scale up your operations or improve the quality of your granules, our team of experts can help you find the perfect solution.

Contact us today to learn more about how our roller compaction systems can optimize your production and meet your specific needs.

Pharmaceutical third party manufacturing is when companies outsource product production to specialized firms. This practice enables companies to focus on research and development. In this guide, we’ll cover the benefits, processes, and considerations of third party manufacturing. Key Takeaways Understanding Pharmaceutical Third Party Manufacturing Pharmaceutical third party manufacturing is a service where a company hires […]

Pharma discovery is crucial for finding new treatments for diseases. This process starts with identifying drug targets and ends with getting safe, effective drugs to market. In this article, we explain each stage of pharma discovery and highlight the innovations transforming this field today. Key Takeaways The drug discovery process is complex and entails multiple […]

If you want to know how do you start a pharmaceutical company, it involves conducting market research, developing a business plan, securing funding, and navigating regulatory requirements. This guide will cover these important steps and more to help you launch and grow a successful pharmaceutical business. Key Takeaways Conduct Comprehensive Market Research Starting a pharmaceutical […]