Apa itu liofilisasi? Liofilisasi adalah metode yang menjaga obat tetap aman. Proses ini juga disebut pengeringan beku. Proses ini membantu obat bertahan lama. Proses ini menghilangkan air sehingga obat dapat bekerja saat dibutuhkan.

Dalam artikel ini, kita akan mempelajari tentang penggunaan liofilisasi dalam industri farmasi. Kita juga akan membahas mengapa hal ini penting untuk obat-obatan.

Butuh mesin Liofilisasi berkinerja tinggi dan dapat diandalkan?

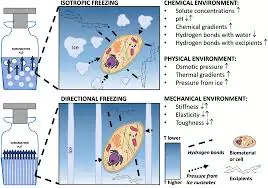

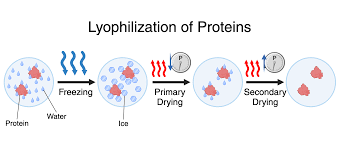

Liofilisasi menghilangkan air dari produk. Pertama, produk dibekukan. Kemudian, tekanan udara diturunkan, sehingga air beku berubah menjadi uap.

Metode ini baik untuk banyak jenis obat. Metode ini membantu menjaga rasa dan nutrisi obat. Dalam pengobatan, liofilisasi membantu menyimpan obat-obatan penting, vaksin, dan protein tanpa kehilangan khasiatnya.

Industri farmasi membutuhkan pembekuan beku. Proses ini menjaga produk tetap stabil dan efektif. Banyak obat dan vaksin tidak tahan panas dan lembap. Obat dan vaksin dapat kehilangan kekuatannya jika tidak disimpan dengan benar.

Liofilisasi memungkinkan produk-produk ini disimpan dengan aman. Produk-produk ini dapat dipindahkan tanpa kehilangan kualitasnya. Hal ini sangat penting untuk obat-obatan yang menyelamatkan nyawa yang harus siap saat pasien membutuhkannya.

Liofilisasi membantu obat bertahan lebih lama. Obat yang diliofilisasi dapat tetap baik selama berbulan-bulan atau bahkan bertahun-tahun tanpa memerlukan lemari es. Ini berguna untuk mengirimnya ke tempat yang jauh.

Dalam keadaan darurat, akses cepat ke obat-obatan dapat menyelamatkan nyawa. Liofilisasi membantu memastikan hal ini terjadi.

Liofilisasi digunakan dalam berbagai cara di bidang farmasi. Berikut adalah delapan penggunaan umum:

Salah satu penggunaan penting adalah pengeringan beku sel mamalia. Proses ini membantu menjaga sel tetap aman untuk penelitian. Menghilangkan air memungkinkan para ilmuwan menyimpan sel lebih lama tanpa kehilangan kemampuan mereka untuk tumbuh.

Hal ini diperlukan untuk eksperimen dan pembuatan produk biologis. Misalnya, para peneliti membekukan sel mamalia untuk digunakan nanti dalam vaksin.

Penggunaan lainnya adalah protein yang dikeringkan dengan pembekuan. Protein dapat sensitif terhadap panas dan kelembapan, yang dapat merusaknya. Liofilisasi menjaga protein tetap stabil dan aktif. Hal ini membuat protein berguna untuk banyak keperluan farmasi.

Protein yang dikeringkan beku mudah dicampur dengan cairan saat dibutuhkan. Ini memastikan protein berfungsi dengan baik. Ini penting untuk enzim dan antibodi yang digunakan dalam pengobatan.

Peptida yang dibekukan juga umum dalam industri farmasi. Peptida adalah rantai kecil asam amino yang digunakan dalam banyak terapi. Ini termasuk perawatan hormon dan terapi kanker. Ketika dibekukan, peptida menjadi stabil dan dapat disimpan untuk waktu yang lama.

Hal ini memudahkan pengangkutan dan penggunaan peptida dalam pengobatan. Meningkatnya penggunaan peptida beku-kering disebabkan oleh efektivitasnya dalam aplikasi medis.

Semaglutide dan tirzepatide membantu mengendalikan diabetes dan berat badan. Obat-obatan ini dapat dibekukan untuk membuatnya stabil. Dengan menghilangkan kelembapan, obat-obatan ini dapat disimpan dengan aman dan digunakan secara efektif.

Pasien mendapatkan manfaat dari masa simpan yang lama dan kemudahan penyimpanan obat versi beku-kering ini. Hal ini penting bagi pasien yang mengandalkan obat ini untuk mengelola kesehatan mereka.

Suntikan beku-kering sering digunakan untuk obat-obatan yang harus stabil hingga digunakan. Saat obat dibekukan, obat dapat dicampur dengan cairan sebelum disuntikkan. Dengan cara ini, pasien akan mendapatkan dosis yang baru dan efektif setiap saat.

Banyak vaksin dan perawatan yang dibuat dengan cara ini agar tetap kuat. Beberapa vaksin perlu dicampur dengan air steril sebelum dapat diberikan.

Mirip dengan protein yang dikeringkan dengan pembekuan, protein yang dikeringkan dengan pembekuan digunakan dalam banyak aplikasi farmasi. Protein ini penting untuk perawatan dan terapi. Dengan mengeringkannya dengan pembekuan, produsen dapat memastikan protein tersebut tetap stabil dan efektif untuk waktu yang lebih lama.

Proses ini sangat penting untuk menghasilkan produk biologis yang andal. Misalnya, antibodi beku-kering yang digunakan dalam imunoterapi dapat disimpan tanpa pendinginan.

Plasma yang dikeringkan beku merupakan aplikasi lain dari pembekuan beku. Plasma dapat disimpan dengan cara ini untuk transfusi darah dan kebutuhan medis lainnya. Saat dibutuhkan, plasma dapat dengan cepat dicampur kembali menjadi cairan. Ini membuatnya siap digunakan dalam keadaan darurat.

Aplikasi ini sangat penting bagi rumah sakit yang membutuhkan akses cepat ke produk darah. Plasma beku-kering sangat penting dalam kasus trauma yang membutuhkan perawatan medis segera.

Terakhir, bakteri yang dikeringkan dengan pembekuan digunakan dalam banyak aplikasi, termasuk penelitian dan farmasi. Dengan membekukan bakteri, para ilmuwan dapat menyimpannya lebih lama. Hal ini sangat membantu untuk vaksin dan produk biologis lainnya yang bergantung pada bakteri hidup.

Proses liofilisasi menjaga bakteri tetap hidup dan efektif saat dibutuhkan. Misalnya, probiotik yang dikeringkan dengan pembekuan dapat digunakan dalam suplemen makanan. Probiotik memberikan manfaat kesehatan saat dicampur dengan cairan.

Meskipun liofilisasi memiliki banyak manfaat, namun juga memiliki beberapa tantangan. Prosesnya bisa mahal dan memerlukan manajemen yang cermat. Produsen harus memastikan bahwa kondisi selama liofilisasi tepat untuk menjaga kualitas produk.

Ke depannya, teknologi baru dapat membantu memecahkan beberapa masalah ini. Kemajuan dalam metode dan peralatan dapat membuat proses ini lebih efisien dan terjangkau. Seiring dengan semakin banyaknya produk yang dikembangkan, liofilisasi akan terus menjadi hal penting dalam industri farmasi.

Penelitian untuk meningkatkan proses liofilisasi dapat menghasilkan cara baru untuk meningkatkan stabilitas produk dan menurunkan biaya. Ini akan membantu memastikan lebih banyak obat dapat diawetkan secara efektif.

Temukan semua mesin Liofilisasi berkinerja tinggi dari Canaan.

Liofilisasi merupakan metode penting dalam industri farmasi. Metode ini membantu menjaga produk tetap aman dan stabil. Dari peptida yang diliofilisasi hingga plasma yang dikeringkan beku, proses ini memastikan obat tetap efektif bagi pasien. Memahami bagaimana liofilisasi digunakan membantu kita melihat pentingnya metode ini dalam perawatan kesehatan.

Bagi mereka yang ingin meningkatkan proses produksi mereka, pertimbangkan untuk menjelajahi peralatan berkualitas tinggi dari Canaan. Kami mengkhususkan diri dalam solusi API dan pelapisan. Anda dapat Hubungi kami hari ini atau pelajari lebih lanjut tentang penawaran kami Di Sini.

Manufaktur pihak ketiga farmasi adalah ketika perusahaan mengalihdayakan produksi produk ke perusahaan spesialis. Praktik ini memungkinkan perusahaan untuk fokus pada penelitian dan pengembangan. Dalam panduan ini, kami akan membahas manfaat, proses, dan pertimbangan manufaktur pihak ketiga. Poin Penting Memahami Manufaktur Pihak Ketiga Farmasi Manufaktur pihak ketiga farmasi adalah layanan di mana perusahaan mempekerjakan […]

Penemuan obat sangat penting untuk menemukan pengobatan baru untuk penyakit. Proses ini dimulai dengan mengidentifikasi target obat dan diakhiri dengan memasarkan obat yang aman dan efektif. Dalam artikel ini, kami menjelaskan setiap tahap penemuan obat dan menyoroti inovasi yang mengubah bidang ini saat ini. Poin Penting Proses penemuan obat itu rumit dan memerlukan banyak […]

Jika Anda ingin tahu cara memulai perusahaan farmasi, Anda harus melakukan riset pasar, mengembangkan rencana bisnis, mendapatkan pendanaan, dan mematuhi persyaratan peraturan. Panduan ini akan membahas langkah-langkah penting ini dan banyak lagi untuk membantu Anda meluncurkan dan mengembangkan bisnis farmasi yang sukses. Poin-poin Penting Lakukan Riset Pasar yang Komprehensif Memulai perusahaan farmasi […]