Pertama, apa itu liofilisasi? Liofilisasi, atau pengeringan beku, adalah proses yang mengawetkan obat-obatan, makanan, dan produk lainnya. Proses ini digunakan untuk menghilangkan kelembapan dari produk sambil menjaganya tetap utuh.

Suhu memegang peranan yang sangat penting dalam proses ini. Jika suhu tidak tepat, produk dapat rusak.

Dalam proses liofilisasi, produk dibekukan, dikeringkan, lalu dikeringkan lagi. Suhu perlu dikontrol pada setiap tahap. Ini membantu mengawetkan produk dan menjaganya tetap aman untuk jangka waktu lama.

Artikel ini akan menjelaskan suhu yang dibutuhkan untuk setiap tahap pembekuan beku. Kami juga akan membahas mengapa kontrol suhu sangat penting.

Butuh mesin Liofilisasi berkinerja tinggi dan dapat diandalkan?

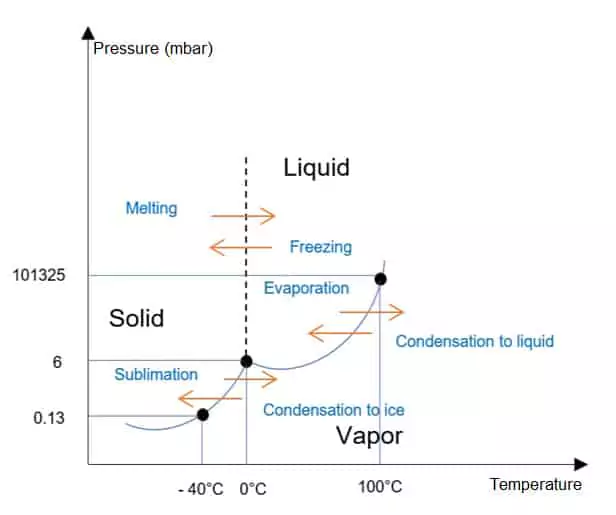

Liofilisasi bekerja dengan menghilangkan air dari suatu produk. Pertama, produk dibekukan menjadi padat. Kemudian, air beku berubah menjadi uap dan meninggalkan produk. Ini menjaga produk tetap kering dan membantunya tetap segar lebih lama.

Suhu sangat penting dalam proses ini. Suhu harus tepat. Jika suhu terlalu tinggi, produk bisa rusak. Jika terlalu rendah, produk mungkin tidak kering dengan baik.

Kontrol suhu membantu menjaga kekuatan produk. Hal ini sangat penting untuk obat-obatan dan vaksin, yang perlu disimpan dengan aman. Liofilisasi membantu memastikan bahwa produk dapat disimpan dalam jangka waktu lama tanpa pendinginan.

Kontrol suhu dalam pembekuan beku merupakan kunci untuk menjaga kestabilan produk. Jika suhu terlalu tinggi, produk dapat rusak. Misalnya, vaksin dapat kehilangan efektivitasnya jika suhu terlalu tinggi selama pembekuan beku.

Jika suhu terlalu rendah, produk mungkin tidak mengering dengan baik. Hal ini dapat menyebabkan sebagian uap air tetap berada dalam produk, yang dapat membuatnya tidak stabil. Liofilisasi bekerja paling baik jika suhu dikontrol dengan hati-hati.

Jika suhu dikontrol dengan benar, produk akan tetap stabil dan aman. Hal ini memastikan efektivitas produk, baik itu vaksin, obat, atau produk sensitif lainnya.

Proses liofilisasi memiliki tiga tahap utama. Suhu yang digunakan berbeda-beda pada setiap tahap. Mari kita lihat suhu untuk setiap tahap.

| Panggung | Kisaran Suhu | Tujuan |

| Tahap Pembekuan | -40°C hingga -80°C (-40°F hingga -112°F) | Bekukan produk sepenuhnya sebelum dikeringkan. |

| Pengeringan Primer | -20°C hingga -40°C (-4°F hingga -40°F) | Hilangkan sebagian besar air dengan mengubah air beku menjadi uap. |

| Pengeringan Sekunder | 20°C hingga 30°C (68°F hingga 86°F) | Hilangkan sisa kelembapan dan stabilkan produk. |

| Pengeringan Akhir | 20°C hingga 30°C (68°F hingga 86°F) | Buang sisa kelembaban terakhir untuk penyimpanan yang stabil. |

Pada tahap pembekuan, produk dibekukan. Suhu sangat rendah untuk memastikan produk benar-benar beku. Suhu pembekuan biasanya antara -40°C dan -80°C (-40°F hingga -112°F). Ini mempersiapkan produk untuk pengeringan.

Selama tahap pengeringan primer, sebagian besar air dikeluarkan dari produk. Suhu dinaikkan sedikit selama tahap ini, biasanya antara -20°C dan -40°C (-4°F hingga -40°F). Ini membantu air beku berubah menjadi uap. Saat air keluar, produk tetap padat dan utuh.

Tahap selanjutnya adalah pengeringan sekunder. Pada tahap ini, sisa air dikeluarkan dari produk. Suhu dinaikkan lebih tinggi lagi, biasanya antara 20°C dan 30°C (68°F hingga 86°F). Ini memastikan produk benar-benar kering dan stabil untuk disimpan.

Setelah pengeringan primer, masih ada sedikit air yang tersisa. Tahap pengeringan akhir menghilangkan sedikit air ini. Suhu dinaikkan antara 20°C dan 30°C (68°F hingga 86°F) selama tahap ini. Langkah ini memastikan produk benar-benar kering dan stabil untuk disimpan.

Kontrol suhu selama proses pembekuan beku sangat penting untuk kualitas produk. Jika suhu terlalu tinggi, bahan aktif produk dapat rusak. Hal ini dapat membuat produk menjadi kurang efektif atau bahkan berbahaya untuk digunakan.

Jika suhu terlalu rendah, produk tidak dapat mengering dengan baik. Sebagian uap air dapat tertinggal di dalam produk, yang dapat menyebabkan kerusakan seiring waktu. Kontrol suhu memastikan bahwa produk dikeringkan dengan baik dan tetap efektif.

Dengan menjaga suhu pada tingkat yang tepat, pembekuan beku membantu mengawetkan obat-obatan dan produk lainnya. Ini membantu memastikan produk tetap efektif dan aman untuk jangka waktu yang lebih lama. Misalnya, vaksin harus tetap berada pada suhu yang tepat agar tetap bermanfaat.

Kontrol suhu dalam proses pengeringan beku bisa jadi sulit. Perubahan suhu yang kecil bisa berdampak besar. Misalnya, jika suhu terlalu tinggi selama pengeringan primer, produk bisa meleleh. Jika terlalu rendah, produk mungkin tidak kering dengan baik.

Produsen memerlukan peralatan yang baik untuk mengendalikan suhu. Peralatan tersebut harus mampu memantau suhu secara ketat dan menyesuaikannya sesuai kebutuhan. Hal ini penting untuk memastikan bahwa produk tidak rusak selama proses berlangsung.

Teknologi telah mempermudah pengendalian suhu selama proses pembekuan beku. Mesin pembekuan beku modern dilengkapi dengan sensor yang mengukur suhu secara langsung. Sensor ini dapat menyesuaikan suhu secara otomatis untuk memastikan suhu tetap pada tingkat yang tepat.

Kemajuan ini membantu mempercepat dan membuat proses lebih akurat. Mesin liofilisasi baru juga membantu menghemat waktu dan uang. Dengan peralatan yang lebih baik, pengendalian suhu menjadi lebih efisien dan efektif.

Seiring dengan terus berkembangnya teknologi, pembekuan beku akan menjadi lebih efisien. Di masa mendatang, kita dapat mengharapkan kontrol suhu yang lebih tepat, yang akan menghasilkan pengawetan produk yang lebih baik.

Kontrol suhu merupakan salah satu bagian terpenting dari pembekuan beku. Kontrol suhu membantu mengawetkan produk dan memastikannya tetap efektif. Dengan mengontrol suhu selama setiap tahap—pembekuan, pengeringan primer, dan pengeringan sekunder—produsen dapat memastikan produk tersebut aman dan stabil.

Jika Anda mencari peralatan yang andal untuk meningkatkan proses liofilisasi Anda, Kanaan memiliki solusi berkualitas tinggi. Peralatan kami membantu mengendalikan suhu secara akurat dan menjaga produk Anda. Pelajari lebih lanjut tentang produk kami dengan mengunjungi situs web kami atau menghubungi bersama kami.

Temukan semua mesin Liofilisasi berkinerja tinggi dari Canaan.

Manufaktur pihak ketiga farmasi adalah ketika perusahaan mengalihdayakan produksi produk ke perusahaan spesialis. Praktik ini memungkinkan perusahaan untuk fokus pada penelitian dan pengembangan. Dalam panduan ini, kami akan membahas manfaat, proses, dan pertimbangan manufaktur pihak ketiga. Poin Penting Memahami Manufaktur Pihak Ketiga Farmasi Manufaktur pihak ketiga farmasi adalah layanan di mana perusahaan mempekerjakan […]

Penemuan obat sangat penting untuk menemukan pengobatan baru untuk penyakit. Proses ini dimulai dengan mengidentifikasi target obat dan diakhiri dengan memasarkan obat yang aman dan efektif. Dalam artikel ini, kami menjelaskan setiap tahap penemuan obat dan menyoroti inovasi yang mengubah bidang ini saat ini. Poin Penting Proses penemuan obat itu rumit dan memerlukan banyak […]

Jika Anda ingin tahu cara memulai perusahaan farmasi, Anda harus melakukan riset pasar, mengembangkan rencana bisnis, mendapatkan pendanaan, dan mematuhi persyaratan peraturan. Panduan ini akan membahas langkah-langkah penting ini dan banyak lagi untuk membantu Anda meluncurkan dan mengembangkan bisnis farmasi yang sukses. Poin-poin Penting Lakukan Riset Pasar yang Komprehensif Memulai perusahaan farmasi […]