It’s essential to understand and implement effective daily maintenance and care measures to extend equipment life. This article will introduce in detail the daily maintenance and care methods of the Fluid-bed Dryer to help you ensure the optimal performance of the equipment.

1. Clean the heater, fan, container, inside and outside of the drying room, cylinder, control cabinet and dust and dirt regularly to keep the equipment clean.

2. Check the oil mist of the air inlet source (air handler) regularly. Add 5# and 7# mechanical oil (transformer oil) to the oil cylinder (on the air outlet side) of the air handler. The oil volume is two-thirds of the total oil mist; if there is water in the water filter, it should be discharged in time.

3. The support bearing of the spray drying chamber should rotate flexibly. The rotating part should be cleaned and 5-8 drops of lubricating oil should be dripped into it every day.

4. When the equipment is not in use, it should be started every fifteen days, and the starting time should not be less than 20 minutes to prevent the solenoid valve, cylinder, etc. from drying up due to long-term lubricating oil, causing damage to the solenoid valve and cylinder.

5. Cleaning: Pull out the raw material container, spray drying chamber, put down the filter bag rack, remove the capture bag, close the damper, clean the materials remaining in various parts of the main machine, especially the gaps on the air flow distribution plate in the raw material container. In particular, the cloth bags should be cleaned and dried in time.

6. If the bag is leaking or damaged or the drying efficiency is low, the bag should be replaced in time.

7. After the bag is installed, the wire rope should be loosened to prevent the wire rope from breaking under stress or damaging the cylinder and other parts.

8. Control the airbag inflation pressure to 0.05-0.1MPa. Too much pressure will damage the airbag.

9. Shake the bag to clean the dust before discharging, and remove the material temperature sensor.

10. Set up the ground wire before starting each time.

11. The total amount of wet material put in each time should be less than 200kg.

12. The operation should be carried out according to the operating steps.

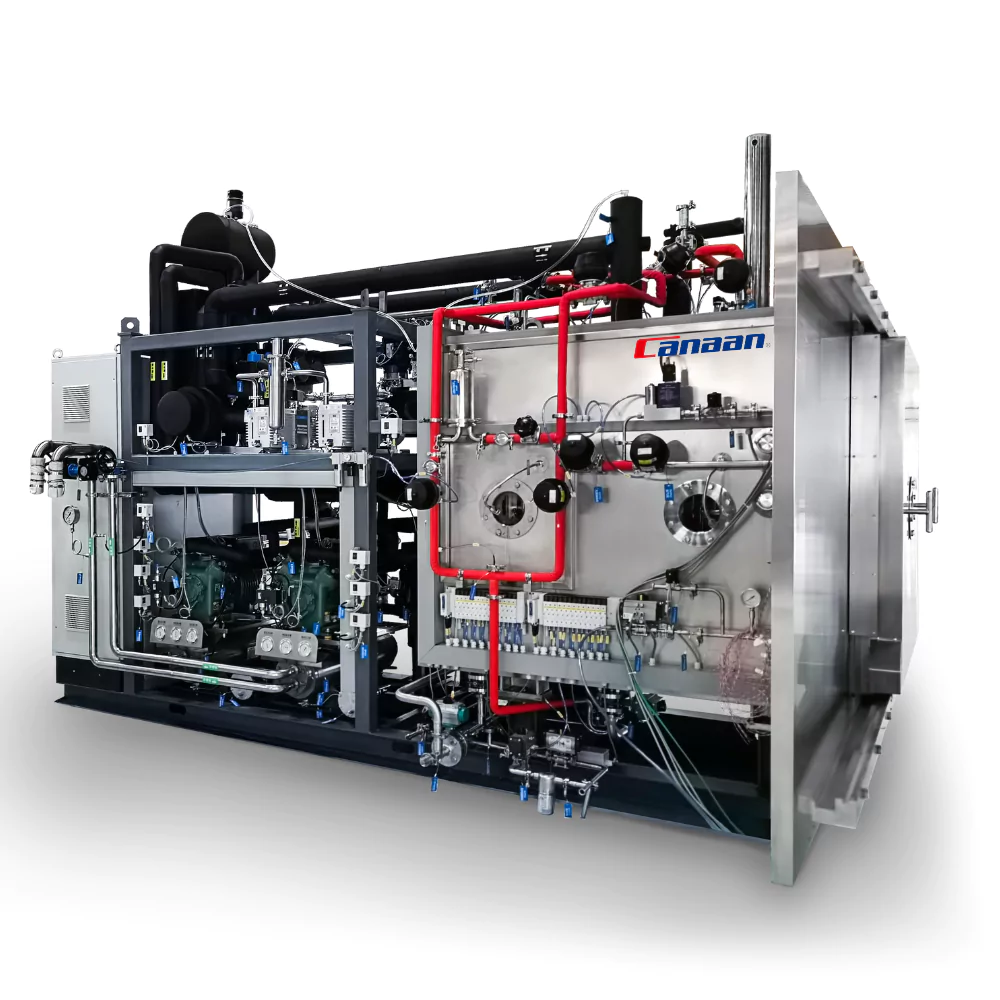

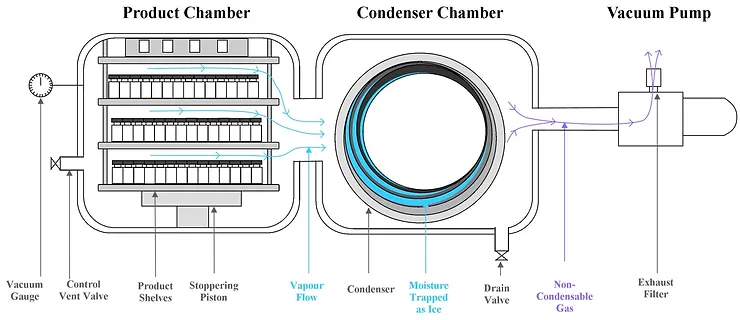

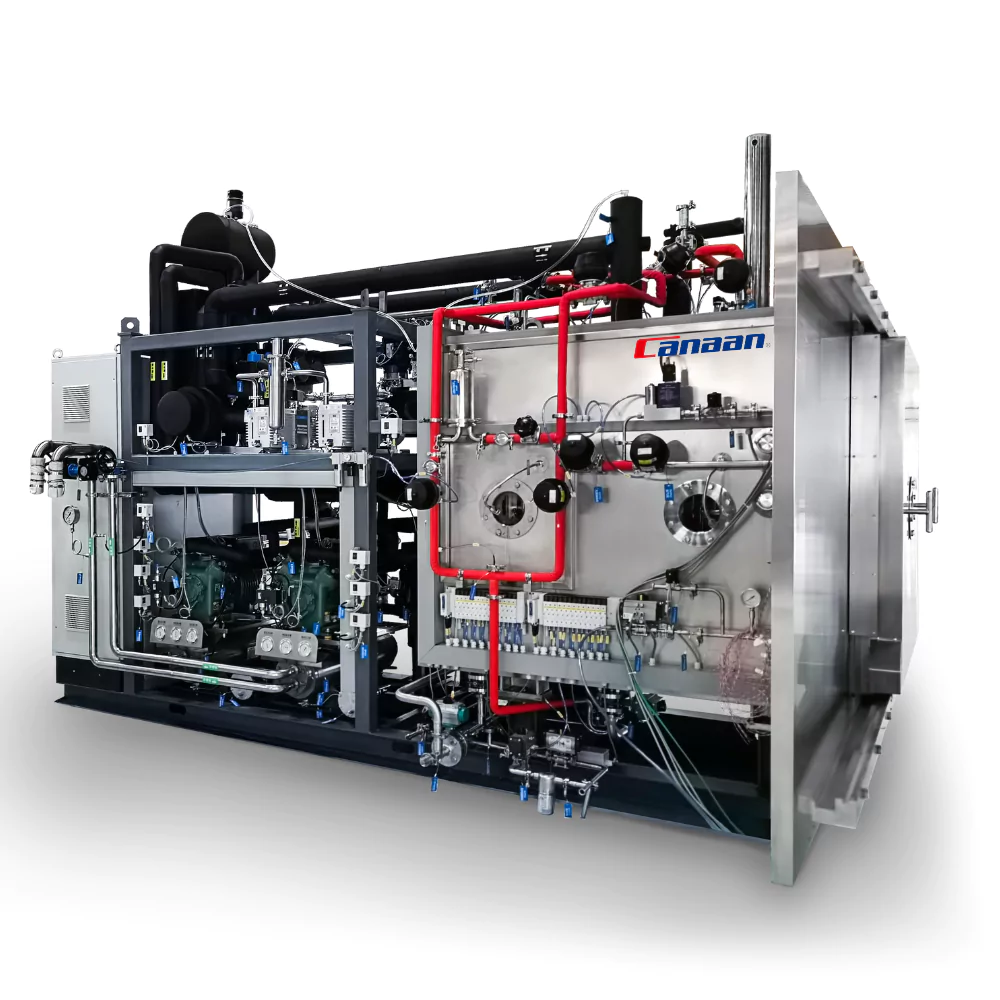

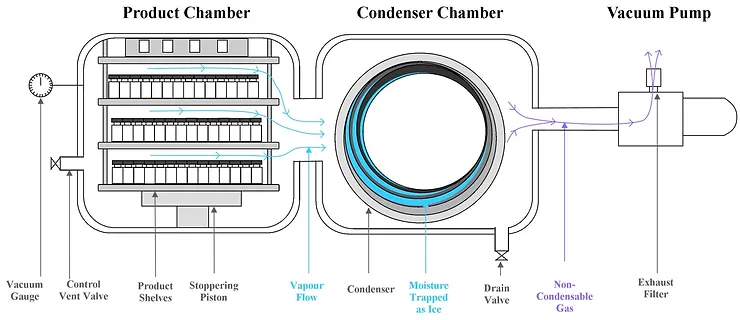

Apa itu liofilisasi? Pengeringan beku, atau liofilisasi, merupakan proses penting dalam industri farmasi. Proses ini membantu mengawetkan obat-obatan, vaksin, dan produk sensitif lainnya dengan menghilangkan kelembapan. Jika Anda membeli mesin pengering beku bekas, penting untuk merawatnya dengan benar. Perawatan yang tepat akan memperpanjang umur mesin, meningkatkan efisiensi, dan memastikan keamanan serta […]

Apa itu pengeringan beku? Pengeringan beku, juga disebut liofilisasi, adalah metode yang digunakan untuk mengawetkan obat-obatan, vaksin, dan produk sensitif lainnya. Metode ini menghilangkan kelembapan dari produk, yang membantu produk tersebut tetap stabil lebih lama. Dalam industri farmasi, pengeringan beku adalah kunci untuk menyimpan produk penting, seperti biologik dan vaksin, tanpa perlu pendinginan. Agar pengeringan beku berfungsi, Anda […]

Dalam industri farmasi, dua metode umum untuk mengeringkan produk adalah pengeringan beku dan pengeringan semprot. Metode ini menghilangkan air dari produk seperti obat-obatan dan vaksin, sehingga lebih awet dan mudah disimpan. Namun, bagaimana cara kerjanya? Dan mana yang lebih baik untuk berbagai jenis produk? Mari kita bahas perbedaan antara pengeringan beku dan pengeringan semprot, […]