コーティングマシンとは何ですか? コーティング機 は製薬業界では欠かせない存在であり、高品質の錠剤やカプセルの製造に重要な役割を果たしています。これらの機械は、錠剤などの固形剤に薄く均一なコーティング材の層を塗布し、錠剤の安定性、外観、機能性を高めます。

この記事では、 コーティング機 作業、そのコンポーネント、およびコーティング プロセスに含まれる重要な手順について説明します。

Canaan のプレミアムコーティングマシンで生産効率を高めましょう。

医薬品製造において、コーティングはいくつかの目的を果たします。

まず第一に、コーティングは薬剤の有効成分を湿気、光、酸素などの環境要因から保護し、薬剤が保存期間中ずっと効果を発揮し続けるようにします。また、コーティングにより錠剤の美観も向上し、患者が飲み込みやすくなり、味や匂いも快適になります。

コーティングは保護に加え、薬剤の放出を制御します。たとえば、コーティング技術によって持続放出または遅延放出製剤が可能になり、より制御された一貫した治療効果が得られます。

適切なものを選択することで コーティング装置製薬会社は、自社製品が品質、安全性、有効性に関する高い基準を満たしていることを保証できます。

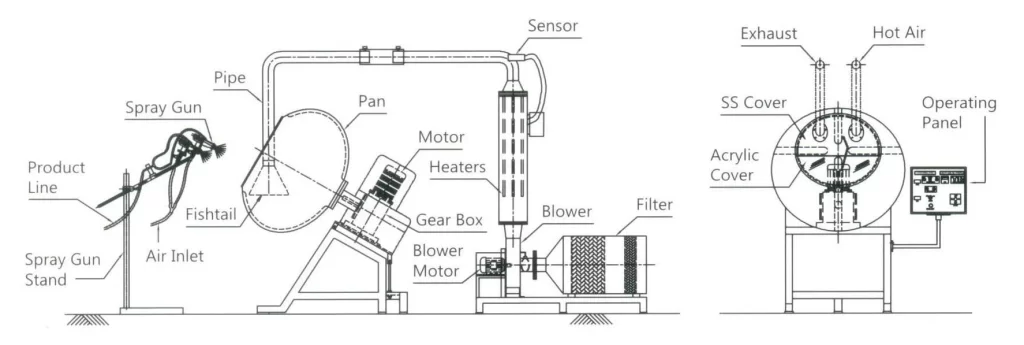

コーティング マシンは、複数の重要なコンポーネントを備えた複雑なシステムであり、各コンポーネントがコーティング プロセスの精度と効率性に貢献します。関係する主なコンポーネントは次のとおりです。

これらの成分が調和して機能し、医薬品基準を満たす均一なコーティングを実現します。

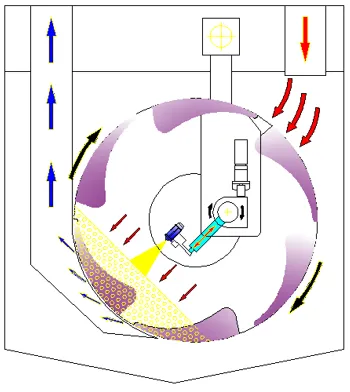

コーティング機の基本的な原理は、錠剤を連続的に動かしながら、コーティング液の微細な霧を噴霧することです。これにより、コーティング液が各錠剤に均一に分散され、加熱された空気が吹き付けられてコーティング液が乾燥します。コーティング工程では通常、複数の層を塗布して、希望する厚さと効果を実現します。

コーティングソリューションは、フィルムコーティングから 砂糖コーティング、に応じて 応用フィルムコーティングは通常薄く、錠剤を環境から保護するために使用されますが、糖衣コーティングは厚く、不快な味を隠すのに適しています。

| ステップ | 説明 |

| 準備 | 錠剤とコーティング溶液(水性または溶剤性)を測定して準備します。 |

| 読み込み中 | 回転コーティングパンに錠剤を投入し、スプレー システムへの均一な露出を確保します。 |

| 温暖化 | 水分を除去してコーティングの密着性を高めるために、錠剤を予熱します。 |

| スプレー | 校正されたノズルを使用して、回転する錠剤にコーティング溶液を均一にスプレーします。 |

| 乾燥 | 加熱空気を使用してコーティングを乾燥させ、各層が欠陥なく固まるようにします。 |

| 繰り返しプロセス | 必要なコーティング層数に達するまで、スプレーと乾燥を繰り返します。 |

| 冷却 | 錠剤を冷却して最終コーティングを硬化させ、固まりを防ぎます。 |

| 放電 | 検査や包装の際には、コーティングを損傷しないように、コーティングされた錠剤を慎重に取り出してください。 |

コーティング機は医薬品製造において不可欠なツールであり、すべての錠剤やカプセルが厳格な品質基準を満たすことを保証します。即放性製剤や徐放性製剤を扱う場合でも、適切なコーティング機があれば、 コーティング装置 生産プロセスの効率と信頼性を大幅に向上できます。

コーティングプロセスを強化する準備はできていますか? お問い合わせ 当社の製品ラインナップをご覧ください コーティング機 最高の業界基準を満たすように設計されています。

製薬サードパーティ製造とは、企業が製品の製造を専門企業にアウトソーシングすることです。この方法により、企業は研究開発に集中できます。このガイドでは、サードパーティ製造の利点、プロセス、考慮事項について説明します。 重要なポイント 製薬サードパーティ製造の理解 製薬サードパーティ製造とは、企業が医薬品の製造を他社に委託するサービスです。一般に契約製造と呼ばれるこの方法により、製薬企業は自社の製造施設に投資することなく製品を市場に投入できます。サードパーティ製造業者とのコラボレーションにより、企業は高度な施設と専門知識を活用して、研究開発などのコアコンピテンシーに集中できます。 […]

医薬品の発見は、病気の新しい治療法を見つけるために不可欠です。このプロセスは、薬物のターゲットを特定することから始まり、安全で効果的な薬を市場に出すことで終わります。この記事では、医薬品の発見の各段階を説明し、今日この分野を変革しているイノベーションに焦点を当てます。重要なポイント医薬品の発見プロセスは複雑で、ターゲットの特定やリードの最適化など、広範な評価と変更を伴う複数の段階を伴います。AIやビッグデータなどの革新的なテクノロジーは、実行可能な薬物候補の特定と開発の最適化の効率を高めることで、医薬品の発見を変革しています。学界と産業界のコラボレーションは、医薬品の発見の課題に対処し、研究方法を改善し、医薬品の発見を加速するために不可欠です。 […]

製薬会社を立ち上げるには、市場調査の実施、事業計画の策定、資金の確保、規制要件の遵守などが必要です。このガイドでは、これらの重要な手順と、製薬ビジネスの立ち上げと成長に役立つその他の手順について説明します。 重要なポイント 包括的な市場調査を実施する 製薬会社を立ち上げるには、適切な市場を特定することから始まります。徹底した市場調査を実施することで、リスクを最大 30% 削減できるため、これは重要な最初のステップになります。世界の製薬市場は、新興市場が重要な役割を果たし、大幅に成長すると予測されています。この成長を活用するには、市場動向を理解し、満たされていないニーズを特定し、競合他社の強みを分析します […]