In the pharmaceutical industry, two common methods for drying products are freeze-drying and spray-drying. These methods remove water from products like medicines and vaccines, making them last longer and easier to store.

But how do they work? And which one is better for different types of products?

Let’s explore the differences between freeze-drying and spray-drying, looking at the pros and cons of each process.

Looking for a lyophilization machine?

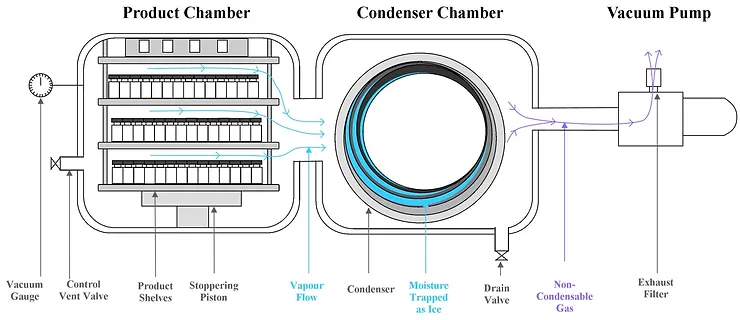

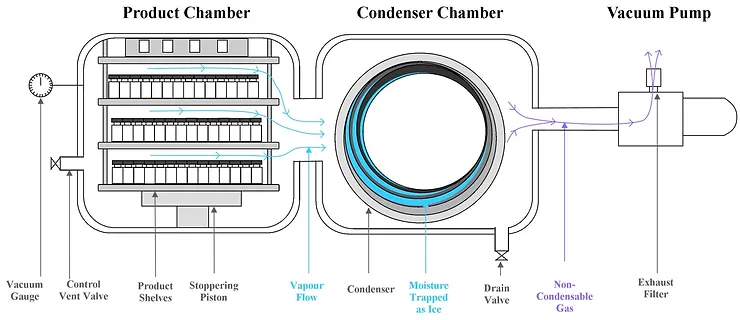

What is freeze-drying? Freeze-drying is a popular method in the pharmaceutical industry. It helps preserve sensitive products by removing water while keeping the product intact. This method is used for many important medicines and vaccines.

Freeze-drying is great for preserving the quality of the product. It keeps the original structure, flavor, and nutrients. This makes it perfect for products like vaccines that need to remain effective for long periods.

Freeze-drying is used for vaccines, proteins, and other biological products. It’s also used in the food industry to preserve fruits, vegetables, and meat without losing flavor.

One of the best things about freeze-drying is how it helps maintain stability. Since most of the moisture is removed, the product can be stored for a long time without refrigeration. This is important for medicines that need to be kept safe and effective.

Freeze-drying takes time. It is a slower process compared to spray drying, which can make it less suitable for producing large amounts of product quickly. However, it’s still the go-to choice when the product must stay stable and maintain its quality.

Freeze-drying can be expensive. The equipment is costly, and it requires more time and energy to complete. This means it may not be the best choice if you need to produce a lot of products quickly or on a tight budget.

Freeze-drying is slow. The product is frozen first, and then water is removed over a long period. This makes it harder to scale up production compared to faster methods like spray drying.

Freeze-dried products usually come in a solid form, such as a powder. After drying, the product can be reconstituted by adding liquid. This is helpful for vaccines and medicines that need to be mixed before use.

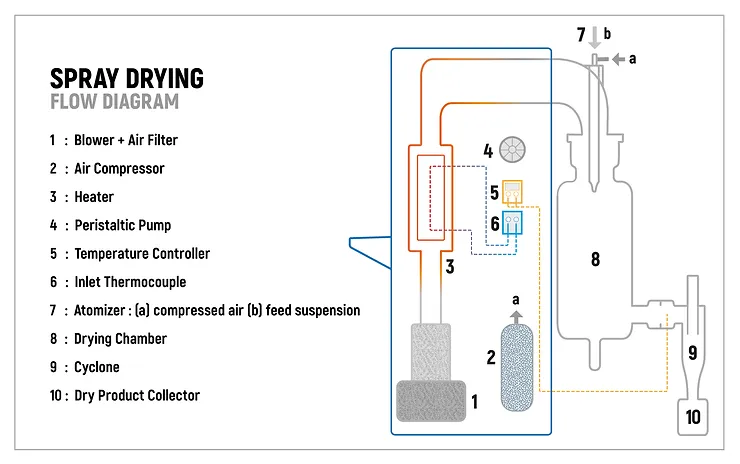

What is spray drying? Spray drying is another drying method used in the pharmaceutical industry. It works by spraying a liquid product into a hot air chamber, where the water quickly evaporates, leaving behind a dry powder.

Spray drying is faster than freeze-drying. It can process a larger volume of products at one time. This makes it a good option when speed is important, or when you need to produce large quantities.

Spray drying is often used to make powders for inhalers, capsules, and tablets. It is also used in the food industry to make powdered milk, coffee, and other products.

Spray drying is good for many products, but it doesn’t preserve the product as well as freeze-drying. Some delicate products, like proteins, might lose their effectiveness when spray-dried. However, for many bulk products, spray drying works very well to keep them stable.

Spray drying is much faster than freeze-drying. It can handle larger quantities of product at once, which makes it better for large-scale production. Spray drying is ideal when you need to produce a lot of products quickly and efficiently.

Spray drying is less expensive than freeze-drying. The equipment is simpler, and the process is faster, so it costs less to operate. This makes spray drying a good option for products that don’t need the high level of preservation that freeze-drying provides.

Spray drying is fast. The liquid product is sprayed into hot air, and the water evaporates quickly. This makes spray drying an ideal choice for fast production cycles.

Spray-dried products are often in the form of fine powders. These powders can be used to make tablets, capsules, or other forms of medicine. Unlike freeze-drying, spray drying doesn’t usually require reconstitution with liquid.

| 要素 | Freeze-Drying | Spray Drying |

| Key Benefits | Preserves product quality, ideal for sensitive items | Faster and more cost-effective for bulk production |

| Typical Applications | Vaccines, proteins, biologics, food preservation | Inhalers, capsules, tablets, powdered food |

| Product Stability | Excellent, maintains integrity for long-term storage | Good, but may not preserve delicate products as well |

| Process Throughput | Slow, suitable for small batches | Fast, suitable for large-scale production |

| Cost Considerations | Expensive due to equipment and time | Less expensive, quicker process |

| Drying Speed | Slow, can take several hours to days | Fast, drying occurs quickly in minutes |

| Product Format | Powder or solid forms, requires reconstitution | Fine powders, ready for direct use without reconstitution |

| Post-Processing Needs | Typically requires reconstitution with liquid | No reconstitution required, ready for use |

Both freeze-drying and spray-drying are useful methods in the pharmaceutical industry. Freeze-drying is better for preserving sensitive products like vaccines and biologics. It helps maintain the product’s quality over time, but it is slower and more expensive.

Spray drying, on the other hand, is faster and more cost-effective. It’s better for producing large quantities of products, especially when speed and cost are important. However, it may not be the best choice for sensitive products that require careful preservation.

If you need reliable equipment for freeze-drying or spray-drying, カナン offers high-quality solutions. Our equipment ensures that your products are preserved properly while maintaining efficiency in the production process.

Visit 当社のウェブサイト または お問い合わせ to learn more!

凍結乾燥とは? 凍結乾燥は、製薬業界では重要なプロセスです。水分を除去することで、医薬品、ワクチン、その他の敏感な製品を保存するのに役立ちます。中古の凍結乾燥機を購入した場合、適切な手入れが不可欠です。適切なメンテナンスにより、機械の寿命が延び、効率が向上し、製品の安全性と品質が確保されます。この記事では、メンテナンスの重要性を説明し、重点的に取り組むべき重要な領域について説明します。中古の凍結乾燥機の状態を評価する 中古の凍結乾燥機または凍結乾燥機のメンテナンスを開始する前に、その状態を評価することが重要です。摩耗の兆候がないか確認し、摩耗がひどい場合は […]

凍結乾燥とは?凍結乾燥は、凍結乾燥とも呼ばれ、医薬品、ワクチン、その他の敏感な製品を保存するために使用される方法です。製品から水分を取り除き、製品をより長く安定させます。製薬業界では、凍結乾燥は、冷蔵を必要とせずに生物製剤やワクチンなどの重要な製品を保管するための鍵です。凍結乾燥を機能させるには、適切な機器が必要です。医薬品凍結乾燥機は、プロセスで使用される主要な機械です。すべてがスムーズに実行されるように、多くの部品が連携して機能します。医薬品凍結乾燥機の8つの主要なコンポーネントを見てみましょう。コンポーネント機能真空チャンバー凍結した水を真空にすることで、水分を除去するために真空を作成します […]

製薬業界では、製品を乾燥させる一般的な方法として、凍結乾燥とスプレー乾燥の 2 つが挙げられます。これらの方法は、医薬品やワクチンなどの製品から水分を取り除き、製品の寿命を延ばし、保管しやすくします。しかし、どのように機能するのでしょうか。また、さまざまなタイプの製品にはどちらが適しているのでしょうか。凍結乾燥とスプレー乾燥の違いについて、それぞれのプロセスの長所と短所を見ながら見ていきましょう。製薬業界における凍結乾燥 凍結乾燥とは 凍結乾燥は、製薬業界でよく使われる方法です。水分を取り除きながら製品をそのままにしておくことで、敏感な製品を保存するのに役立ちます。この方法は、多くの重要な医薬品やワクチンに使用されています。主な利点 凍結乾燥は、 […]