Dalam industri farmaseutikal, dua kaedah biasa untuk pengeringan produk ialah pengeringan beku dan pengeringan semburan. Kaedah ini mengeluarkan air daripada produk seperti ubat-ubatan dan vaksin, menjadikannya tahan lebih lama dan lebih mudah disimpan.

Tetapi bagaimana mereka berfungsi? Dan yang manakah lebih baik untuk pelbagai jenis produk?

Mari kita terokai perbezaan antara pengeringan beku dan pengeringan semburan, melihat kebaikan dan keburukan setiap proses.

Mencari mesin lyophilization?

Apakah pengeringan beku? Pengeringan beku adalah kaedah yang popular dalam industri farmaseutikal. Ia membantu memelihara produk sensitif dengan mengeluarkan air sambil mengekalkan produk itu utuh. Kaedah ini digunakan untuk banyak ubat dan vaksin penting.

Pengeringan beku sangat bagus untuk mengekalkan kualiti produk. Ia mengekalkan struktur asal, rasa dan nutrien. Ini menjadikannya sesuai untuk produk seperti vaksin yang perlu kekal berkesan untuk tempoh yang lama.

Pengeringan beku digunakan untuk vaksin, protein dan produk biologi lain. Ia juga digunakan dalam industri makanan untuk memelihara buah-buahan, sayur-sayuran dan daging tanpa kehilangan rasa.

Salah satu perkara terbaik tentang pengeringan beku ialah cara ia membantu mengekalkan kestabilan. Oleh kerana kebanyakan kelembapan dikeluarkan, produk boleh disimpan untuk masa yang lama tanpa penyejukan. Ini penting untuk ubat-ubatan yang perlu disimpan dengan selamat dan berkesan.

Pengeringan beku mengambil masa. Ia adalah proses yang lebih perlahan berbanding dengan pengeringan semburan, yang boleh menjadikannya kurang sesuai untuk menghasilkan sejumlah besar produk dengan cepat. Walau bagaimanapun, ia masih menjadi pilihan utama apabila produk mesti kekal stabil dan mengekalkan kualitinya.

Pengeringan beku boleh jadi mahal. Peralatan ini mahal, dan memerlukan lebih banyak masa dan tenaga untuk disiapkan. Ini bermakna ia mungkin bukan pilihan terbaik jika anda perlu menghasilkan banyak produk dengan cepat atau pada bajet yang ketat.

Pengeringan beku adalah perlahan. Produk dibekukan dahulu, dan kemudian air dikeluarkan dalam tempoh yang lama. Ini menjadikannya lebih sukar untuk meningkatkan pengeluaran berbanding kaedah yang lebih cepat seperti pengeringan semburan.

Produk kering beku biasanya datang dalam bentuk pepejal, seperti serbuk. Selepas pengeringan, produk boleh dibentuk semula dengan menambah cecair. Ini berguna untuk vaksin dan ubat-ubatan yang perlu dicampur sebelum digunakan.

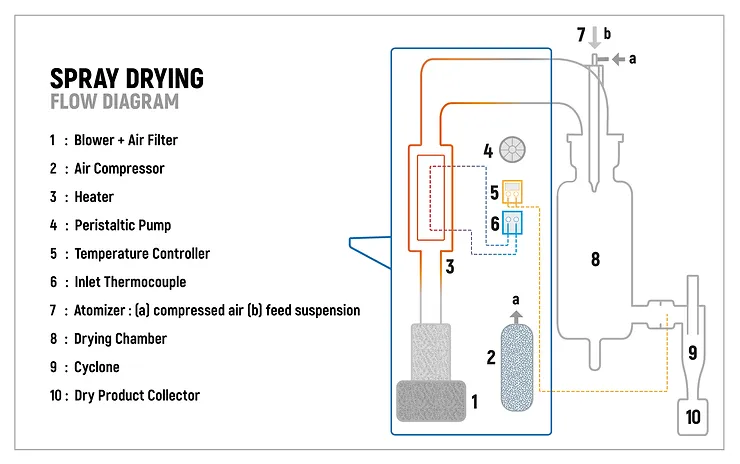

Apakah pengeringan semburan? Pengeringan semburan adalah kaedah pengeringan lain yang digunakan dalam industri farmaseutikal. Ia berfungsi dengan menyembur produk cecair ke dalam ruang udara panas, di mana air cepat menyejat, meninggalkan serbuk kering.

Pengeringan semburan lebih cepat daripada pengeringan beku. Ia boleh memproses jumlah produk yang lebih besar pada satu masa. Ini menjadikannya pilihan yang baik apabila kelajuan adalah penting, atau apabila anda perlu menghasilkan kuantiti yang banyak.

Pengeringan semburan sering digunakan untuk membuat serbuk untuk penyedut, kapsul dan tablet. Ia juga digunakan dalam industri makanan untuk membuat susu tepung, kopi, dan produk lain.

Pengeringan semburan bagus untuk banyak produk, tetapi ia tidak mengekalkan produk serta pengeringan beku. Sesetengah produk halus, seperti protein, mungkin kehilangan keberkesanannya apabila disembur kering. Walau bagaimanapun, untuk kebanyakan produk pukal, pengeringan semburan berfungsi dengan baik untuk memastikannya stabil.

Pengeringan semburan adalah lebih cepat daripada pengeringan beku. Ia boleh mengendalikan kuantiti produk yang lebih besar sekaligus, yang menjadikannya lebih baik untuk pengeluaran berskala besar. Pengeringan semburan sesuai apabila anda perlu menghasilkan banyak produk dengan cepat dan cekap.

Pengeringan semburan lebih murah daripada pengeringan beku. Peralatannya lebih ringkas, dan prosesnya lebih cepat, jadi kos operasinya lebih murah. Ini menjadikan pengeringan semburan pilihan yang baik untuk produk yang tidak memerlukan tahap pemeliharaan yang tinggi yang disediakan oleh pengeringan beku.

Pengeringan semburan adalah cepat. Produk cecair disembur ke udara panas, dan air menyejat dengan cepat. Ini menjadikan pengeringan semburan pilihan ideal untuk kitaran pengeluaran yang cepat.

Produk semburan kering selalunya dalam bentuk serbuk halus. Serbuk ini boleh digunakan untuk membuat tablet, kapsul, atau bentuk ubat lain. Tidak seperti pengeringan beku, pengeringan semburan biasanya tidak memerlukan penyusunan semula dengan cecair.

| Faktor | Pengeringan beku | Pengeringan Sembur |

| Faedah Utama | Memelihara kualiti produk, sesuai untuk item sensitif | Lebih cepat dan lebih menjimatkan kos untuk pengeluaran pukal |

| Aplikasi Biasa | Vaksin, protein, biologi, pengawetan makanan | Inhaler, kapsul, tablet, makanan serbuk |

| Kestabilan Produk | Cemerlang, mengekalkan integriti untuk penyimpanan jangka panjang | Baik, tetapi mungkin tidak mengekalkan produk yang halus juga |

| Throughput Proses | Perlahan, sesuai untuk kumpulan kecil | Cepat, sesuai untuk pengeluaran berskala besar |

| Pertimbangan Kos | Mahal kerana peralatan dan masa | Lebih murah, proses lebih cepat |

| Kelajuan Pengeringan | Perlahan, boleh mengambil masa beberapa jam hingga beberapa hari | Cepat, pengeringan berlaku dengan cepat dalam beberapa minit |

| Format Produk | Serbuk atau bentuk pepejal, memerlukan penyusunan semula | Serbuk halus, sedia untuk digunakan terus tanpa penyusunan semula |

| Keperluan Selepas Pemprosesan | Biasanya memerlukan penyusunan semula dengan cecair | Tiada penyusunan semula diperlukan, sedia untuk digunakan |

Kedua-dua pengeringan beku dan pengeringan semburan adalah kaedah yang berguna dalam industri farmaseutikal. Pengeringan beku adalah lebih baik untuk memelihara produk sensitif seperti vaksin dan biologi. Ia membantu mengekalkan kualiti produk dari semasa ke semasa, tetapi ia lebih perlahan dan lebih mahal.

Pengeringan semburan, sebaliknya, lebih cepat dan lebih menjimatkan kos. Ia lebih baik untuk menghasilkan produk dalam kuantiti yang banyak, terutamanya apabila kelajuan dan kos adalah penting. Walau bagaimanapun, ia mungkin bukan pilihan terbaik untuk produk sensitif yang memerlukan pemeliharaan yang teliti.

Jika anda memerlukan peralatan yang boleh dipercayai untuk pengeringan beku atau pengeringan semburan, Kanaan menawarkan penyelesaian berkualiti tinggi. Peralatan kami memastikan produk anda dipelihara dengan baik sambil mengekalkan kecekapan dalam proses pengeluaran.

melawat laman web kami atau hubungi kami untuk mengetahui lebih lanjut!

Pengilangan pihak ketiga farmaseutikal ialah apabila syarikat menyumber luar pengeluaran produk kepada firma khusus. Amalan ini membolehkan syarikat memberi tumpuan kepada penyelidikan dan pembangunan. Dalam panduan ini, kami akan merangkumi faedah, proses dan pertimbangan pembuatan pihak ketiga. Pengambilan Utama Memahami Pembuatan Pihak Ketiga Farmaseutikal Pengilangan pihak ketiga farmaseutikal ialah perkhidmatan di mana syarikat mengupah […]

Penemuan farmasi adalah penting untuk mencari rawatan baharu untuk penyakit. Proses ini bermula dengan mengenal pasti sasaran dadah dan berakhir dengan mendapatkan ubat yang selamat dan berkesan untuk dipasarkan. Dalam artikel ini, kami menerangkan setiap peringkat penemuan farmasi dan menyerlahkan inovasi yang mengubah bidang ini hari ini. Pengambilan Utama Proses penemuan dadah adalah kompleks dan memerlukan pelbagai […]

Jika anda ingin tahu bagaimana anda memulakan syarikat farmaseutikal, ia melibatkan menjalankan penyelidikan pasaran, membangunkan rancangan perniagaan, mendapatkan pembiayaan dan menavigasi keperluan kawal selia. Panduan ini akan merangkumi langkah-langkah penting ini dan banyak lagi untuk membantu anda melancarkan dan mengembangkan perniagaan farmaseutikal yang berjaya. Pengambilan Utama Menjalankan Penyelidikan Pasaran Komprehensif Memulakan farmaseutikal […]