Capsule coating technology is an importantprocess in the pharmaceutical industry, used to pack and protect drugs orhealth care products. It forms a protective film by covering the outer layer ofthe drug to enhance its stability, improve the appearance and taste of thedrug, and help delay the release of the drug. However, due to the significantdifferences in the structure and surface material of the capsule compared toordinary tablets, the difficulties encountered by capsule coating in the actualprocess will be more prominent than those of ordinary tablet coating – unevendrug application, capsule delamination, bubbles, etc.

Uneven drug application has always been amajor challenge for capsule coating. Traditional capsule coating equipmentusually uses a common single impeller to conduct spray while the capsule flows,so that drugs can be distributed on the surface of the capsule. However, due tofactors such as the size and density difference of capsules, as well as theinfluence of centrifugal force during rotation, capsules can not be fullymixed, and some capsules are difficult to be brought to the spray area by the impeller,which makes the overall drug application uneven.

Due to the material of the capsule bodyand the internal filling material, the surface of the capsule is prone tovarious defects, such as ink spots, bubbles, spots, delamination, and collapse.Except for the situation where the compatibility between the coating materialand the capsule body is not strong, the occurrence of defects is basically dueto the imprecise control accuracy of the coating process. Under the conditionof consistent atomization uniformity (the spray system of Canaan Technology’s fullseries of coaters can ensure that the atomization consistency between eachspray gun is more than 97%), if the ambient temperature and humidity and thenegative pressure of the pot body change, the drugs inside the capsule body andthe capsule body are likely to shrink or expand accordingly, resulting invarious defects.

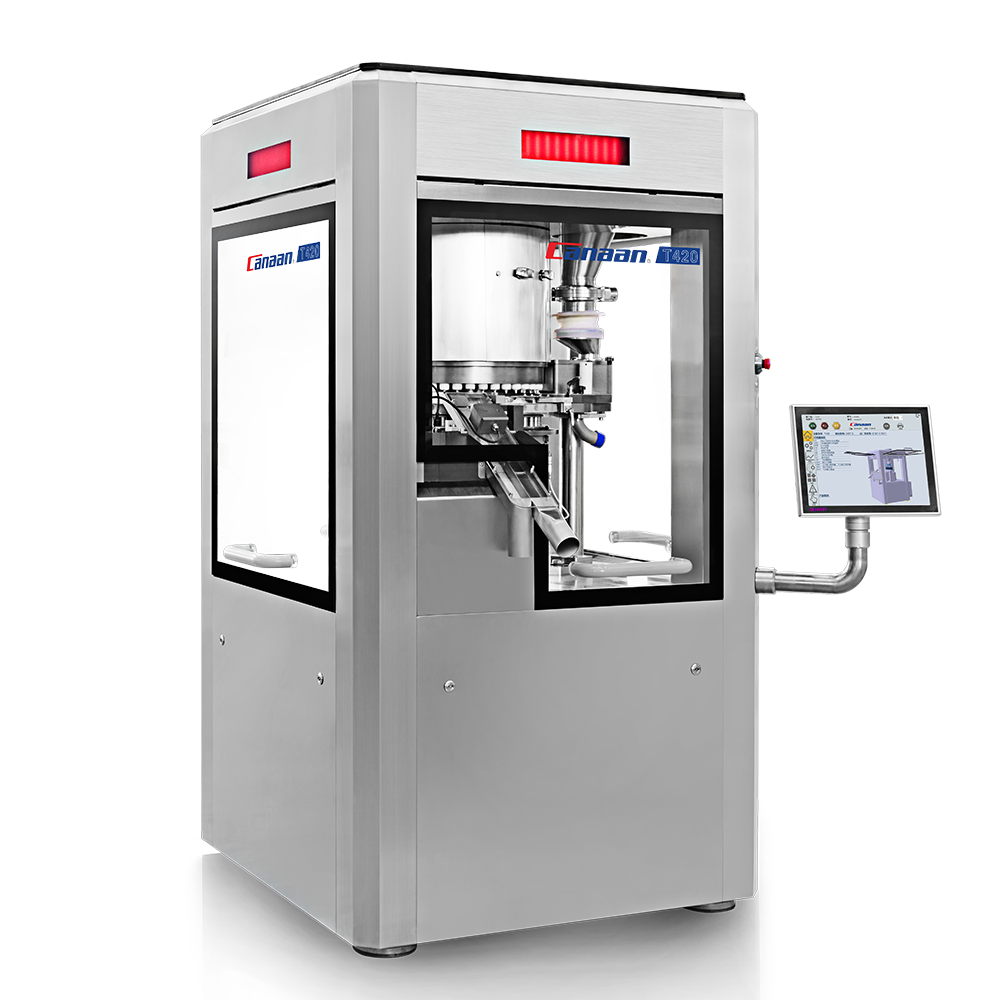

Canaan Technology has solved thedifficulties in capsule coating through innovation in coater technology andprocess.

Multiple combinations ofimpellers improve the uniformity of drug application

In order to overcome the problem ofuniformity in drug application, Canaan Technology has devoted itself toresearch and practice, and developed customized multi combinations of impellers

Thecustomized multi-combination impellers is designed according to the physicalproperties of the capsule and the coating process requirements. This kind of impellershas a special shape and structure, which can better “divert” thecapsules, so that the capsules can flip back and forth inside the drum morefully. During the rotation, stronger shear force and centrifugal force aregenerated, thereby making the medicine more Best evenly distributed on thecapsule surface.

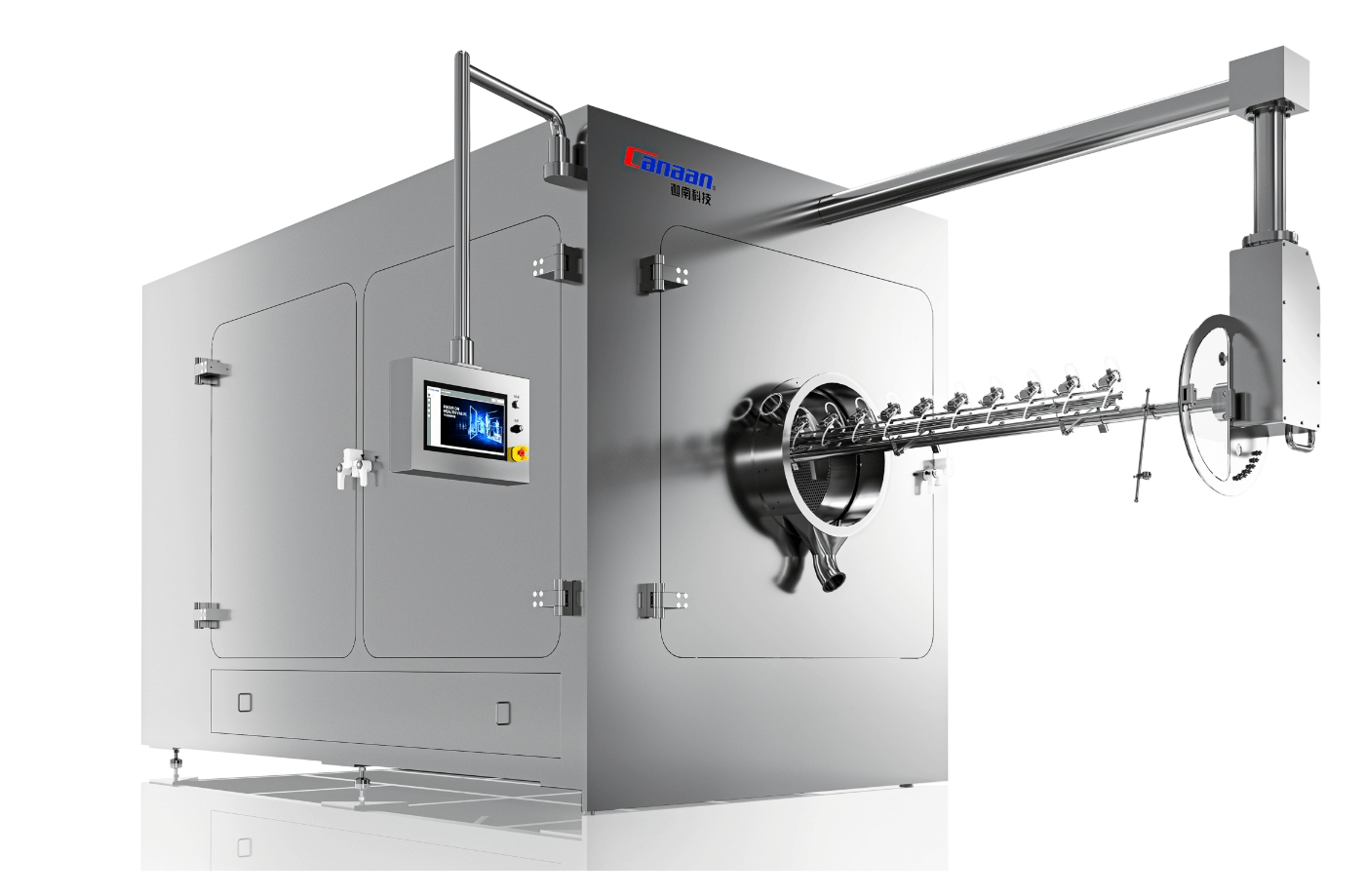

High precision parametercontrol reduces surface defects

CanaanTechnology’s full range of coaters are equipped with the TechproM V4 operatingsystem. This system has achieved breakthroughs in terms of operating logic, technicalarchitecture, and function implementation. It deeply integrates technicaladvantages such as digital operating systems, intelligent optimization, andadvanced industrial networks. It accurately and stably controls each processparameter value, monitors and stores process parameters in the coating processin real time, and has highly sensitive sensing capabilities, which can quicklyrespond and remind abnormal situations in the entire process.

Paired with top international brandcontrol valve groups, Canaan Technology has taken the lead in parameter controlaccuracy in the coating process from both software and hardware aspects. As ofnow, the control accuracy of Canaan Technology’s coaters is:

Temperature: ± 1 ℃; (If the steam supplyis stable, it can meet ± 0.5 ℃)

Humidity: ± 0.5g/kg;

Air volume: ± 3%;

Negative pressure: ± 10Pa.

Manufacturers andpharmaceutical companies strengthen cooperation to optimize process formulas

Canaan Technology has more than tenprofessional process engineers, most of whom have been immersed in the field ofcoating for more than ten years. They have extensive experience in coating andare able to identify anomalies in the process from minor quality issues ofproducts.

Duringthe research and development of a certain customer’s capsule drug, CanaanTechnology had in-depth exchanges with the customer and participated in theentire coating process. By studying coating thickness, quality, stability,optical properties, etc., we optimize coater and refine the process toultimately meet customer needs for capsule coating.

In thefuture, Canaan Technology will continue to research and optimize coater technology,improve process flow, increase cooperation between pharmaceutical companies andmanufacturers, continuously explore and innovate through a large amount ofexperimental data, combined with different types of tablets, and strive tobring better operational experience to customers and better pharmaceuticalequipment to humanity.

The 15th Vogel Pharmaceutical Engineering International Forum was grandly held in Nanjing, China

The BGX Series Coater newly launched by Canaan Technology in recent years are fully in line with the current market situation.