The CFK-1500 series capsule filling machine is a fully automatic capsule filling machine newly developed by Canaan, incorporating advanced domestic and international technology. This equipment features an attractive design, smooth operation, low noise, and is easy to operate and clean.

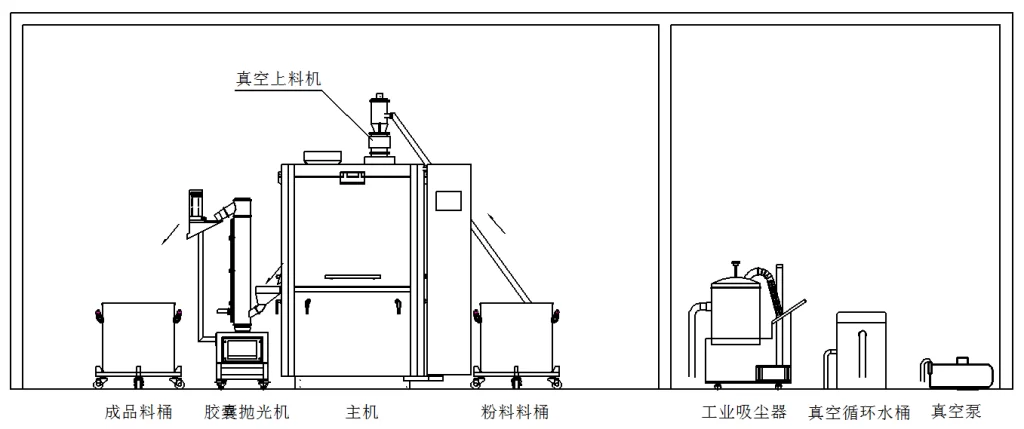

The entire machine uses an intermittent rotary mechanism and a tamping method for quantitative filling. It is suitable for filling powder and granules into capsules ranging from size 00# to 5#. Optional auxiliary equipment, such as an automatic capsule feeder, vacuum feeder, metal detector, polisher, and elevator, can also be added.

| Output | 1500Capsules/min |

| No.of segment bores | 11 |

| Suitable fof capsule | 00#-5# |

| Total power | 8.5Kw |

| Overall weight | 1400Kgs |

| Overall diemensions | 1230mm×1175(+382)mm×1955mm |

| Dust | 20Kpa 210m3/h |

| Noise | <80DB(A) |

| Vacuum | 72m3/h, -0.03—0.05Mpa |

| Filling error | ±2.5%—±3.5% |

The capsule feeding tube is equipped with multiple circular channels inside, which are connected to the capsule hopper. Inside the channels, there are capsule clamping tabs.

As the capsule feeding tube moves up and down in a reciprocating motion, empty capsules fall into the channels. When the feeding tube moves upward, the clamping tabs hold the capsules in place. When the tube moves downward, the clamping tab assembly rotates, releasing the capsules, allowing them to drop out of the channels.

The capsule feeder head always acts on the middle of the capsule body. As the feeder head pushes the capsule, it causes the capsule to turn, ensuring that the capsule body is pushed to the edge of the capsule feeder comb. The capsule is then flipped over as the pressing head moves downward, pushing it vertically into the module hole.

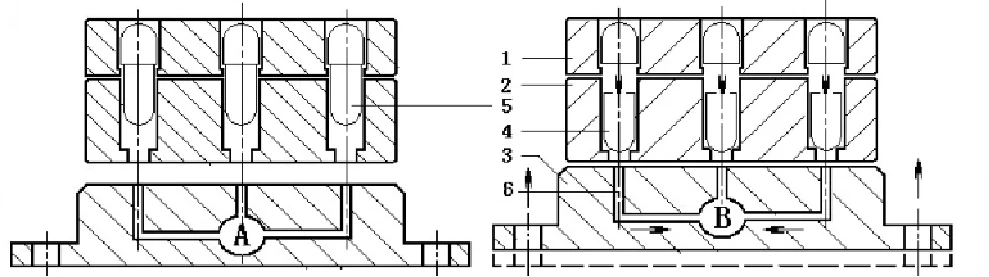

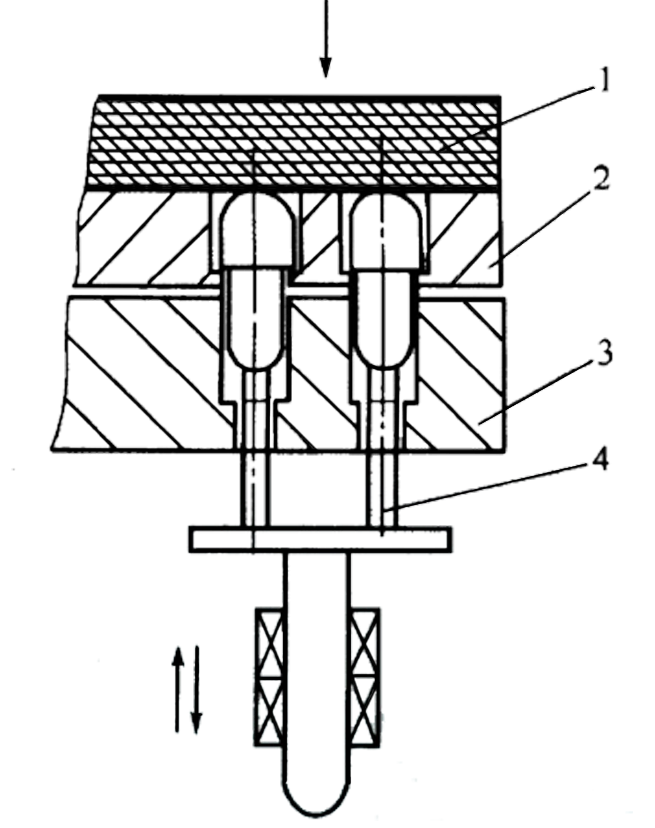

When the empty capsule enters the module hole, the vacuum suction seat rises and seals tightly with the lower module. The diameters of the small stepped holes in the upper and lower modules are smaller than the diameters of the capsule cap and body, respectively. Once the vacuum is activated, the capsule body is sucked into the hole of the lower module, while the step in the hole of the upper module prevents the capsule cap from descending. This results in the separation of the capsule body and cap.

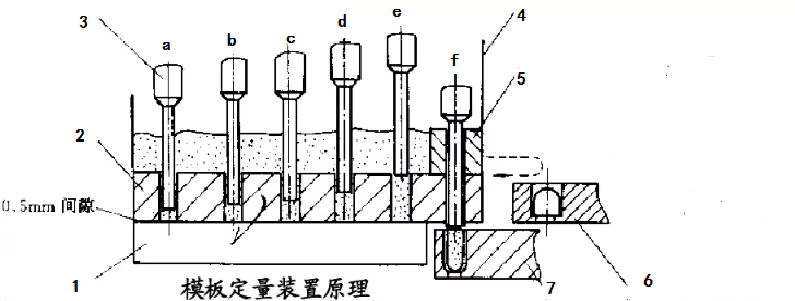

Letters a-f represent different groups of tamping pins. During the intermittent period when the pins rise, the powder hopper rotates by a certain angle. As it completes a full rotation, the powder in the dosing disk holes is compressed once by each group of tamping pins. When the pins lift from the holes, the hopper rotates again, and the powder on the dosing disk automatically fills the remaining space in the holes. This process—filling and compressing—repeats until the sixth tamping, when the pin ejects the powder column from the dosing disk, dropping it into the empty capsule body below, completing one filling cycle.

The relative motion between the scraper and the dosing disk removes any excess powder on the surface of the dosing disk, ensuring that the powder column meets the measurement requirements.

Occasionally, some empty capsules may fail to separate the cap from the body for various reasons. These capsules, which are not filled with medication, remain in the upper module hole. To prevent these defective capsules from mixing with the finished products, they are removed before the capsule closure process.

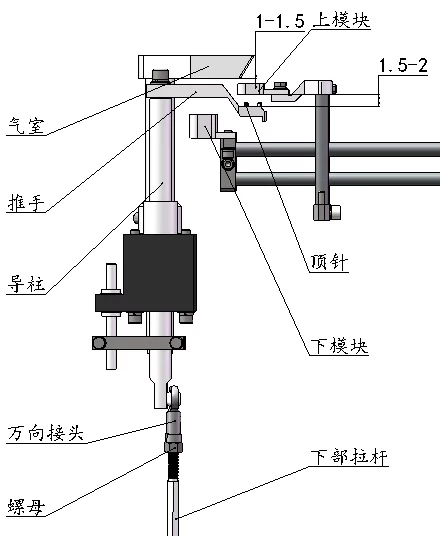

A reciprocating pusher is located between the upper and lower modules. The pusher is equipped with a pin. As the upper and lower modules rotate, the pusher stays in the lower position, with the pin disengaged from the upper module. When the module stops at this station, the pusher moves upward, and the pin attached to the pusher is inserted into the hole in the upper module.

The purpose of this station is to lock and seal the filled capsules by engaging the capsule cap with the body, ensuring the finished product meets the required standards.

The upper and lower modules rotate together to the capsule locking station, where their axes align. The upper stopper above the module and the pushing rod below begin to move toward each other. The upper stopper presses down on the capsule cap while the pushing rod ascends, causing the capsule cap and body to close and lock securely.

The purpose of this station is to eject the fully sealed and locked finished capsules, which are then collected.

The main component of this device is a reciprocating ejection rod. When the upper and lower modules carrying the closed capsules rotate to the ejection station and stop, the ejection rod pushes the capsules out of the module holes. The capsules are then blown into the discharge chute and slide into the collection container.

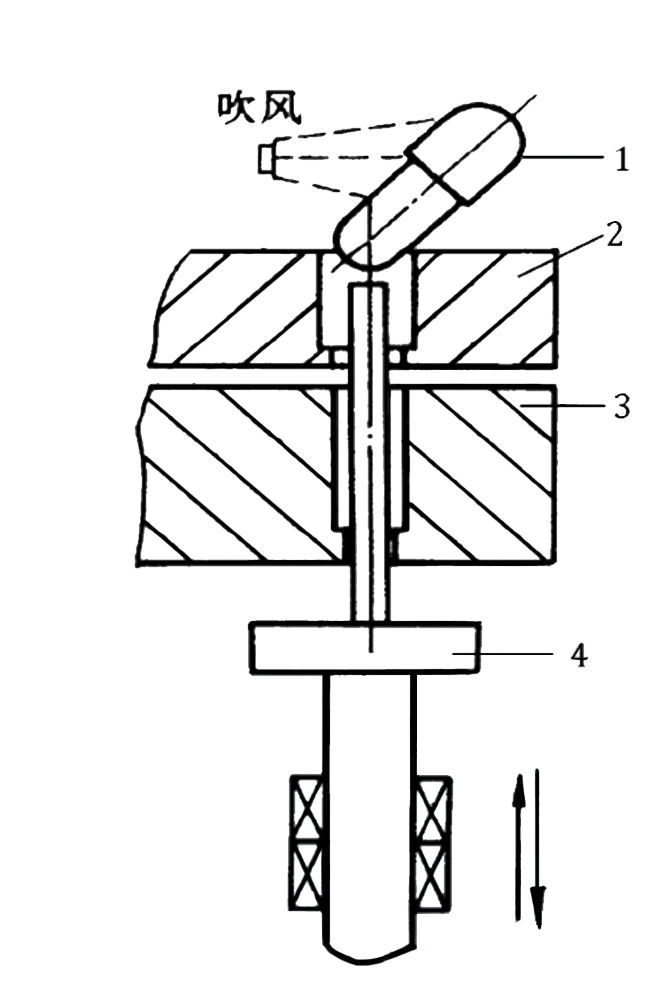

The cleaning station is designed to clean the modules in preparation for the next cycle.

When the upper and lower modules are driven by the main working platform and stop at the cleaning station, they align with the opening of the cleaning device. At this point, compressed air is activated to blow out any powder, broken capsule fragments, and other contaminants from the module holes in the lower module. The vacuum system positioned above the module holes then sucks these contaminants into the vacuum cleaner, ensuring that the module holes remain clean for the next operational cycle.

Model |

CFK1500C |

CFK2500 |

CFK3500 |

| Capacity (Capsules/hr.) | 90000 | 150000 | 210000 |

|

Weight (kg) |

1400 | 1650 | 2500 |

| Machine dimensions(mm) | 1230*1175(+382)*1955 | 1435(+550)*1248(+280)*1960 | 1435(+550)*1248(+280)*1960 |

| Power supply | 380/220V 50Hz | 380/220V 50Hz | 380/220V 50Hz |

| Motor power | Motor 2.2KW | Motor 2.2KW | Motor 4.4KW |

| Vacuum 3KW | Vacuum 3KW | Vacuum 4KW | |

| Dust collection 2.2KW | Dust collection 2.2KW | Dust collection 2.2KW | |

| No.of segment bores | 11 | 18 | 25 |

| Vacuum | Pumping rate 72m³/h, -0.03~-0.05Mpa |

Pumping rate 72m³/h, -0.03~-0.05Mpa |

Pumping rate 120m³/h, -0.03~-0.05Mpa |

| Dust collecting | 20Kpa 210m³/h | 20Kpa 210m³/h | 20Kpa 210m³/h |

| Noise | <75DB(A) | <75DB(A) | <75DB(A) |

| Qualified rate | Empty capsule 99%, full capsule more than 98% |

Empty capsule 99%, full capsule more than 98% |

Empty capsule 99%, full capsule more than 98% |

| Suitable capsules | 000,00,0,1,2,3,4,5# | 000,00,0,1,2,3,4,5# | 000,00,0,1,2,3,4,5# |

| Filling deviation | ±2.5%-±3.5% | ±2.5%-±3.5% | ±2.5%-±3.5% |